Product categories

- Polymer Borealis

- Polypropylene (PP) Borealis

- Polypropylene Borealis

- Mineral Reinforced Borealis

- Ethylene Vinyl Acetate Borealis

- Film Borealis

- Polyethylene (PE) Borealis

- HDPE Borealis

- High Density Polyethylene (HDPE) Borealis

- Injection Molded Borealis

- Elastomer Borealis

- TPE Borealis

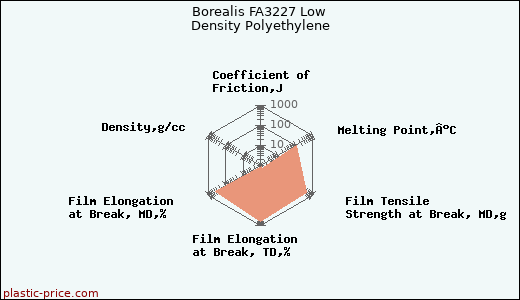

- LDPE Borealis

- Low Density Polyethylene (LDPE) Borealis

- Film Grade Borealis

- LLDPE Borealis

- Extruded Borealis

- Molded Borealis

- Polyolefin Borealis

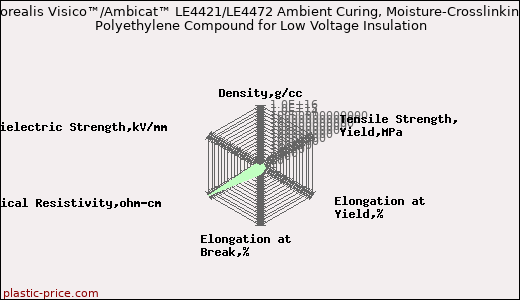

- Wire/Cable Grade Borealis

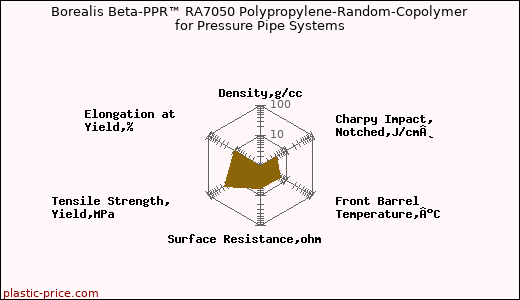

- Polypropylene Copolymer Borealis

- Ethylene Butyl Acrylate Borealis

- UHMW PE Ultra High Molecular Weight Borealis

- Linear Low Density Polyethylene (LLDPE) Borealis

- MDPE Borealis

- Rotational Molded Borealis

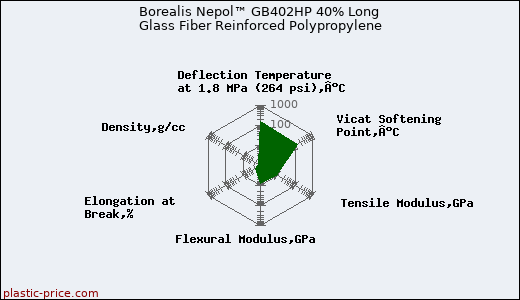

- Polypropylene with 30% Glass Fiber Filler Borealis

- Extrusion Grade Borealis

- Medium Density Polyethylene (MDPE) Borealis

- Blow Molding Grade Borealis

- Pipe Grade Borealis

- Impact Modified; Molded/Extruded Borealis

- Thermoplastic Olefinic Elastomer (TPO) Borealis

- Polypropylene with 20% Glass Fiber Filler Borealis

- TPO Borealis

- Polypropylene with 40% Glass Fiber Filler Borealis

- Polypropylene with 20% Mica Filler Borealis

Thermoplastic Borealis

$ 1633/MT

- Density: 0.900 g/cc

- Linear Mold Shrinkage: 0.013 cm/cm

- Linear Mold Shrinkage: 0.014 cm/cm

- Melt Flow: 2.2 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 65.0 MPa

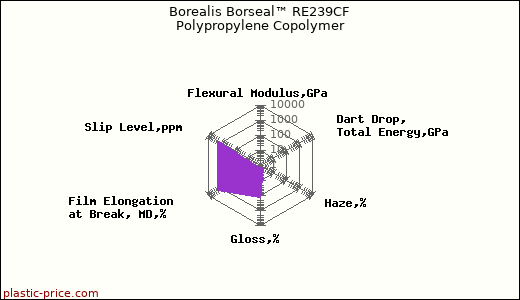

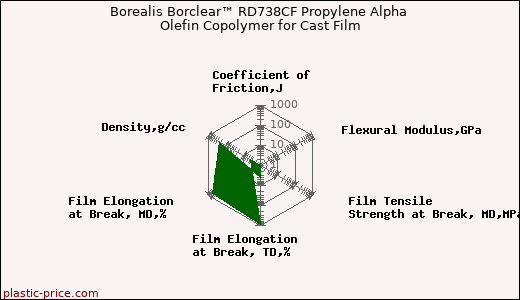

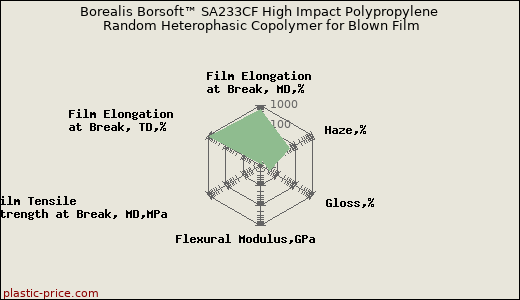

$ 1565/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 1.5 g/10 min @Load 2.16 kg, Temperature 230 °C

- Film Elongation at Break, MD: 550 - 600 %

- Tensile Modulus: 0.730 GPa

- Flexural Modulus: 0.650 GPa

$ 1677/MT

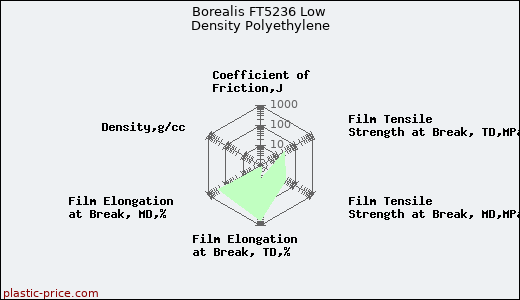

- Density: 0.928 g/cc

- Thickness: 40.0 microns

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 190 °C

- Film Elongation at Break, MD: 300 %

- Film Elongation at Break, TD: 550 %

$ 2187/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.0015 cm/cm

- Linear Mold Shrinkage: 0.014 cm/cm

- Melt Flow: 11 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Shore D: 55

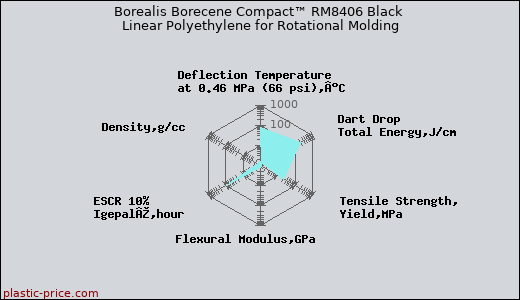

$ 1495/MT

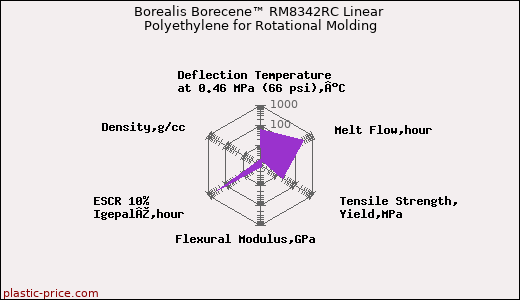

- Density: 0.940 g/cc

- Linear Mold Shrinkage: 0.0085 - 0.0095 cm/cm

- Melt Flow: 12 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 35.0 MPa

- Tensile Strength, Yield: 16.50 MPa

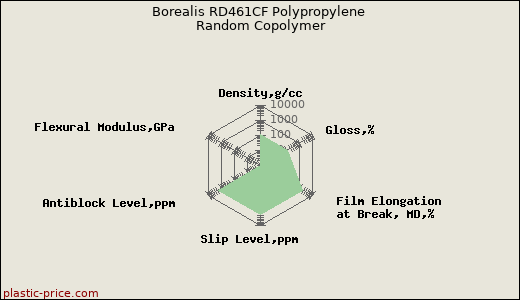

$ 1832/MT

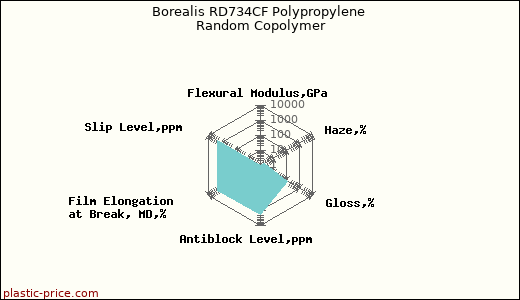

- Density: 0.922 g/cc

- Melt Flow: 4.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Antiblock Level: 1100 ppm

- Slip Level: 700 ppm

- Film Elongation at Break, MD: 400 %

$ 1559/MT

- Density: 0.936 g/cc

- Oxidative Induction Time (OIT): >= 40 min

- High Load Melt Index: 10 g/10 min @Load 21.6 kg, Temperature 190 °C

- Tensile Strength, Yield: 22.00 MPa

- Elongation at Yield: 10 %

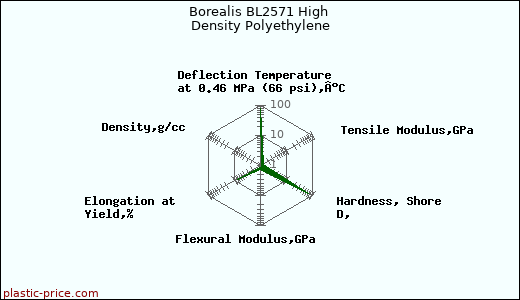

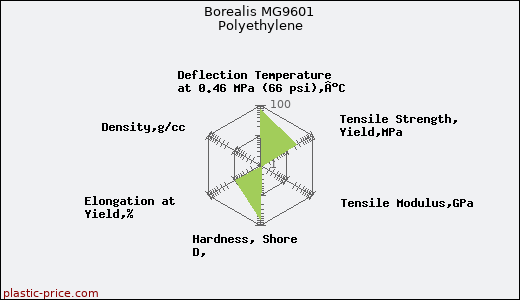

$ 1545/MT

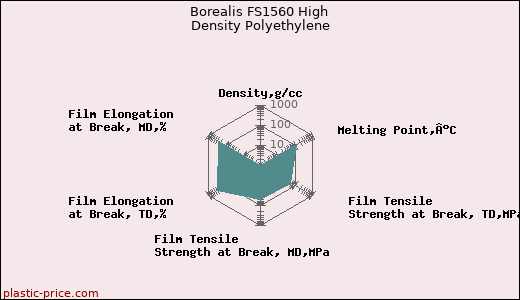

- Density: 0.964 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 63

- Tensile Strength, Yield: 27.0 MPa

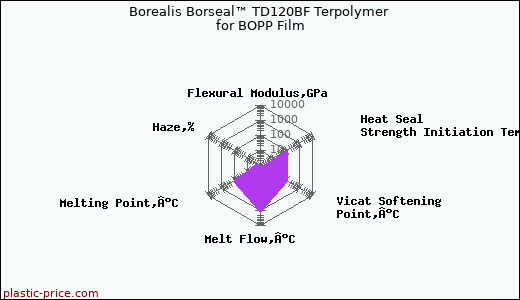

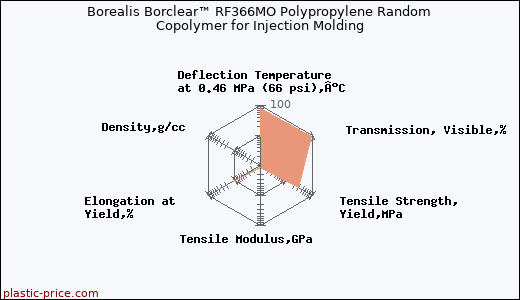

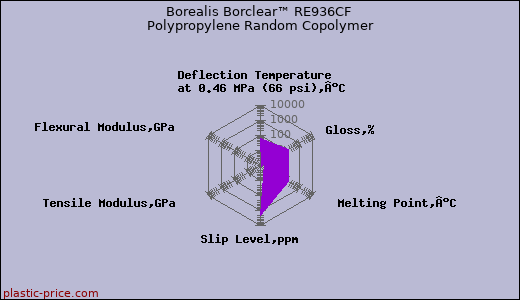

$ 2272/MT

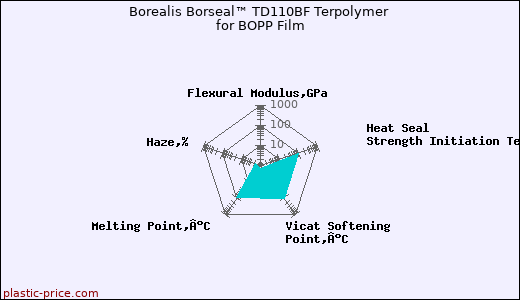

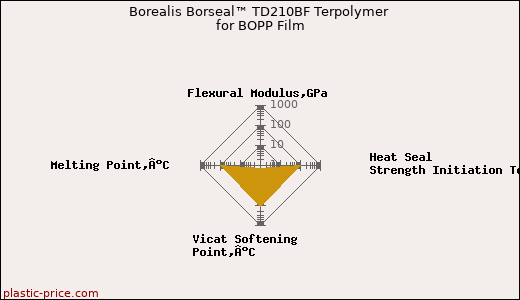

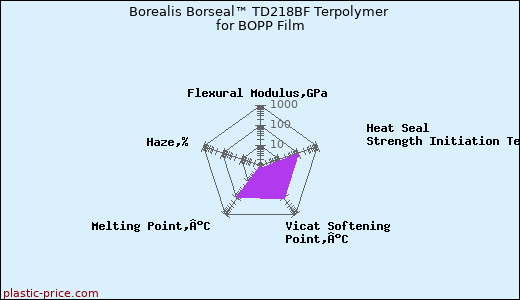

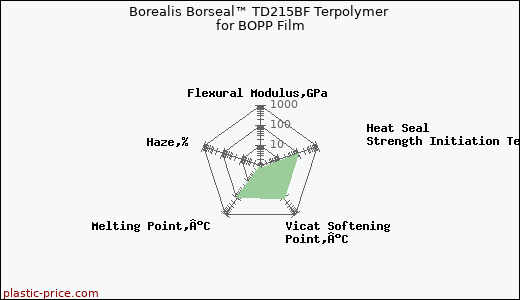

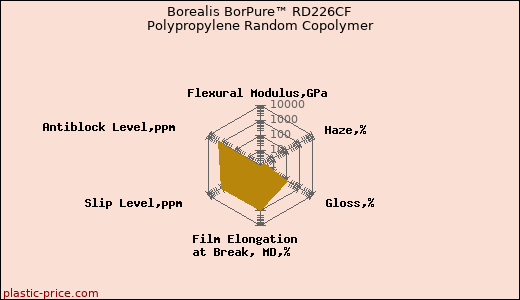

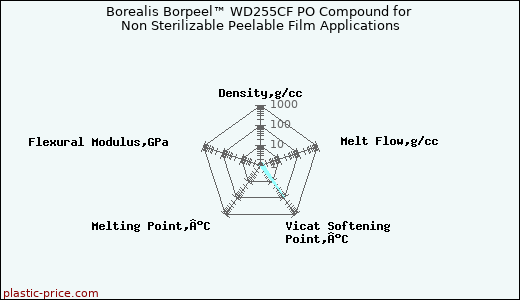

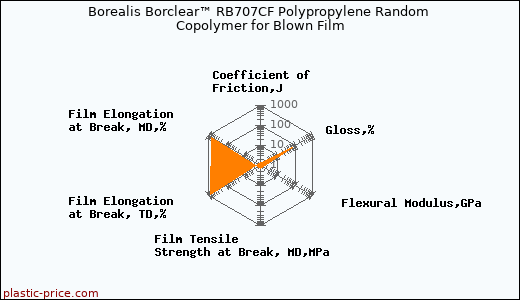

- Melt Flow: 6.5 g/10 min @Load 2.16 kg, Temperature 230 °C

- Flexural Modulus: 0.700 GPa

- Heat Seal Strength Initiation Temperature: 103 °C

- Melting Point: 128 - 132 °C

- Vicat Softening Point: 114 °C

- Haze: 1.8 %

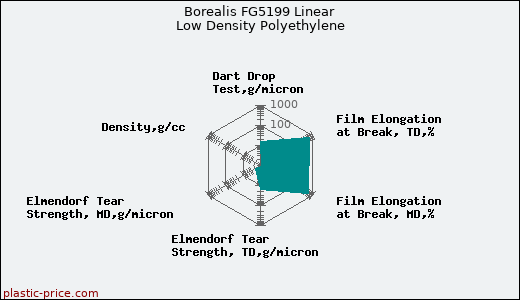

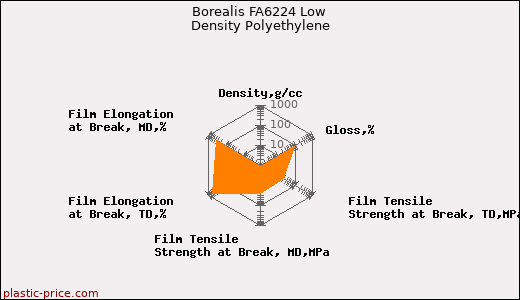

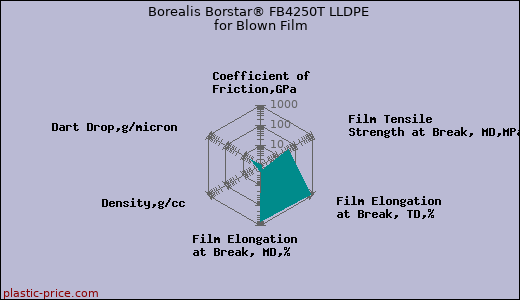

$ 1552/MT

- Density: 0.919 g/cc

- Melt Flow: 1.25 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength, Yield: 11.0 MPa

- Film Elongation at Break, MD: 550 %

- Film Elongation at Break, TD: 710 %

$ 1829/MT

- Density: 1.04 g/cc

- Linear Mold Shrinkage: 0.010 cm/cm

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 30 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 57.0 MPa

$ 1477/MT

- Density: 1.17 g/cc

- Linear Mold Shrinkage: 0.0010 cm/cm

- Melt Flow: 20 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 10.0 MPa

- Elongation at Break: 450 %

$ 1872/MT

- Density: 0.948 g/cc

- Environmental Stress Crack Resistance: >= 5.0 hour @Pressure 0.800 MPa, Temperature 80.0 °C

- Oxidative Induction Time (OIT): >= 20 min @Temperature 200 °C

- Melt Flow: 0.40 g/10 min @Load 5.00 kg, Temperature 190 °C

- Tensile Strength, Yield: 19.0 MPa

$ 2501/MT

- Density: 1.01 g/cc

- Linear Mold Shrinkage: 0.010 cm/cm

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 30 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 50.0 MPa

$ 1499/MT

- Density: 1.01 g/cc

- Linear Mold Shrinkage: 0.010 cm/cm

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 30 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 50.0 MPa

$ 1861/MT

- Density: 1.01 g/cc

- Linear Mold Shrinkage: 0.010 cm/cm

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 30 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 50.0 MPa

$ 2190/MT

- Density: 1.01 g/cc

- Linear Mold Shrinkage: 0.010 cm/cm

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 30 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 50.0 MPa

$ 1837/MT

- Density: 1.01 g/cc

- Linear Mold Shrinkage: 0.010 cm/cm

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 30 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 50.0 MPa

$ 2319/MT

- Density: 1.01 g/cc

- Linear Mold Shrinkage: 0.010 cm/cm

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 30 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 50.0 MPa

$ 2036/MT

- Density: 1.01 g/cc

- Linear Mold Shrinkage: 0.010 cm/cm

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 30 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 50.0 MPa

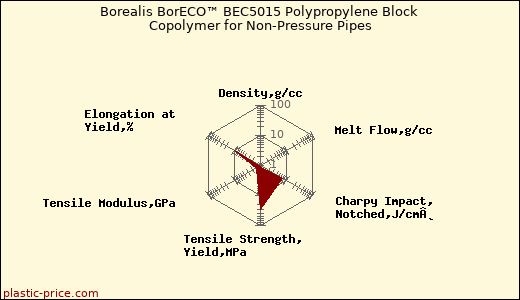

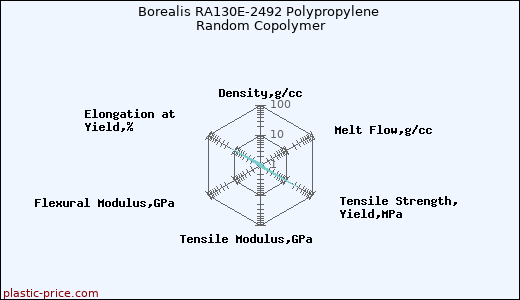

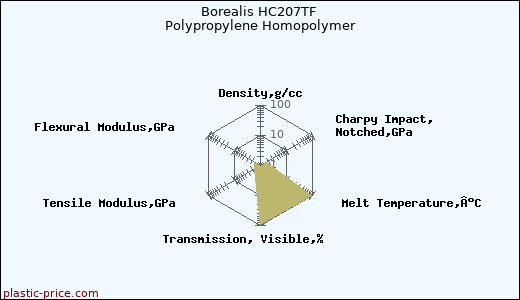

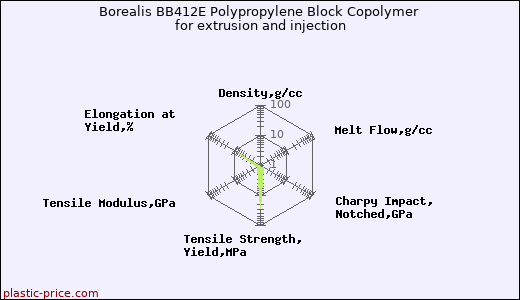

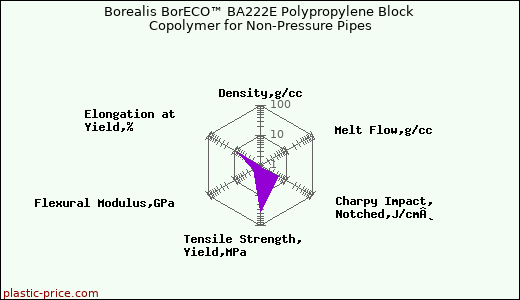

$ 1453/MT

- Density: 0.902 g/cc

- Melt Flow: 1.5 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 24.0 MPa

- Tensile Modulus: 0.900 GPa

- Charpy Impact, Notched: 2.00 J/cm² @Temperature 23.0 °C

$ 1456/MT

- Density: 0.923 g/cc

- Water Vapor Transmission: 8.00 g/m²/day

- Oxygen Transmission Rate: 5000 cc/m²/day

- Thickness: 40.0 microns

- Melt Flow: 0.20 g/10 min @Load 2.16 kg, Temperature 190 °C

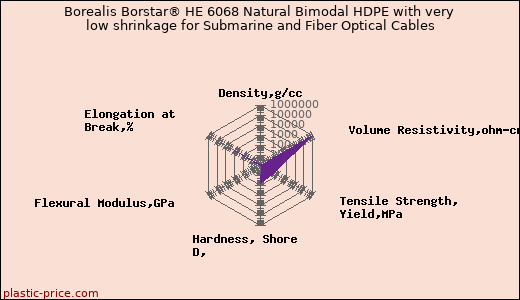

$ 2341/MT

- Density: 0.954 g/cc

- Melt Flow: 0.30 g/10 min @Load 5.00 kg, Temperature 190 °C

$ 1501/MT

- Density: 0.931 g/cc

- Water Vapor Transmission: 6.00 g/m²/day

- Oxygen Transmission Rate: 3500 cc/m²/day

- Thickness: 40.0 microns

- Melt Flow: 0.20 g/10 min @Load 2.16 kg, Temperature 190 °C

$ 2366/MT

- Density: 0.950 g/cc

- Density: 0.960 g/cc

- ESCR 10% Igepal®: >= 10000 hour

- Carbon Black Loading: 2.0 %

- Melt Flow: >= 0.10 g/10 min @Load 2.16 kg, Temperature 190 °C

$ 1569/MT

- Density: 0.943 g/cc

- Environmental Stress Crack Resistance: >= 2000 hour @Temperature 80.0 °C

- Melt Flow: 0.90 g/10 min @Load 5.00 kg, Temperature 190 °C

- Tensile Strength, Yield: 19.00 MPa

- Tensile Modulus: 0.800 GPa

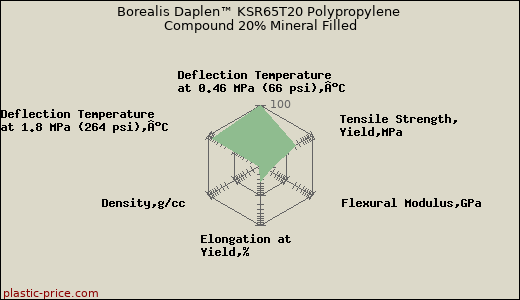

$ 1510/MT

- Density: 1.13 g/cc

- Linear Mold Shrinkage: 0.0090 cm/cm

- Melt Flow: 2.5 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 11.2 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 71.0 MPa

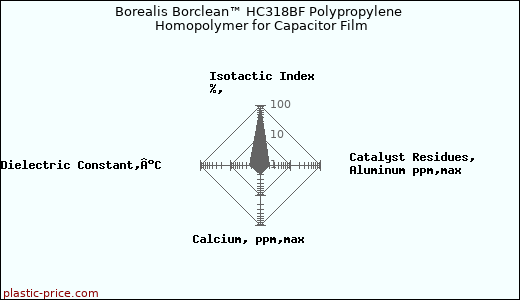

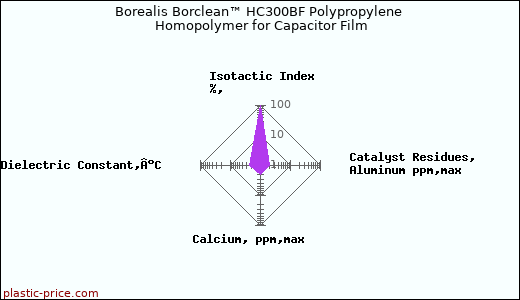

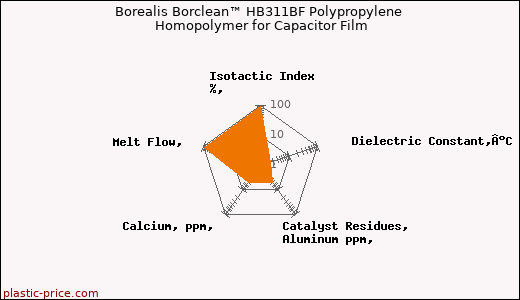

$ 2486/MT

- Melt Flow: 3.7 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ash: 0.0010 - 0.0020 %

- Melting Point: 161 - 165 °C

- Dielectric Constant: 2.25

- Calcium, ppm: 5

$ 2136/MT

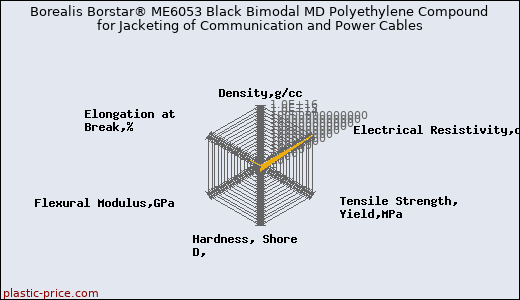

- Density: 0.948 g/cc

- Density: 0.959 g/cc

- Environmental Stress Crack Resistance: >= 5.0 hour @Pressure 0.920 MPa, Temperature 80.0 °C

- Oxidative Induction Time (OIT): >= 20 min @Temperature 210 °C

- Carbon Black Loading: 2.0 - 2.5 %

$ 1899/MT

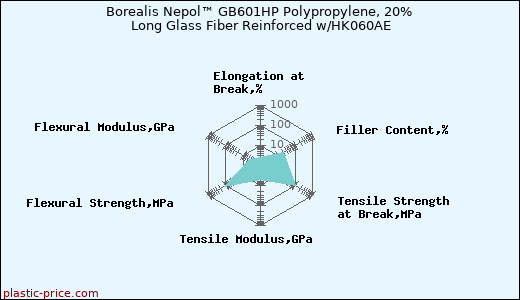

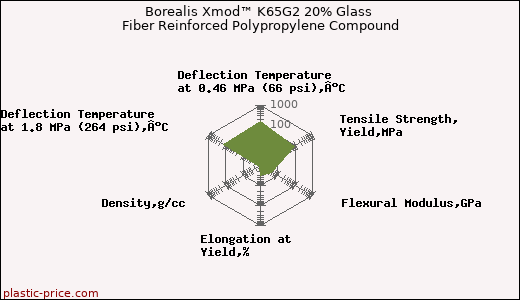

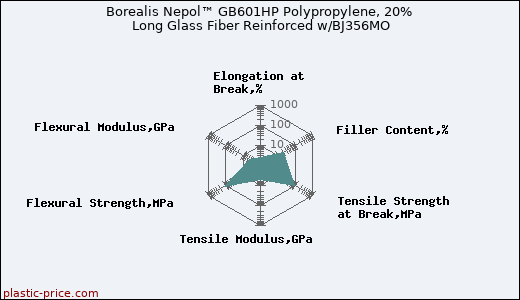

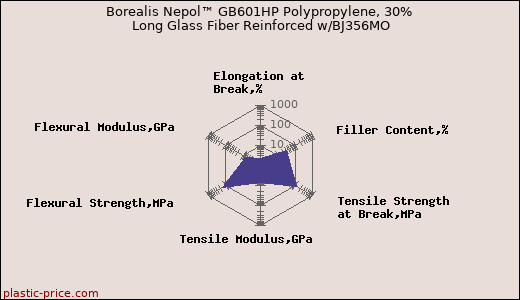

- Filler Content: 20 %

- Tensile Strength at Break: 100 MPa

- Elongation at Break: 2.5 %

- Tensile Modulus: 5.30 GPa

- Flexural Strength: 130 MPa

$ 1938/MT

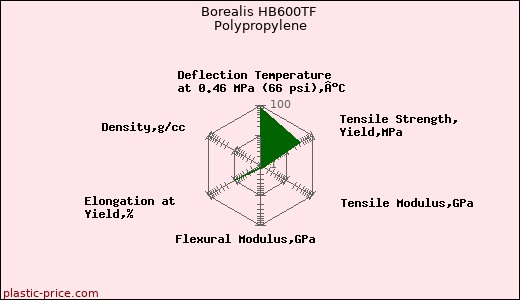

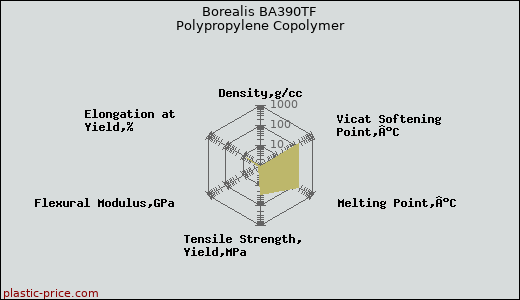

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.015 - 0.020 cm/cm

- Melt Flow: 2.8 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 39.50 MPa

- Elongation at Yield: 7.0 %

$ 1551/MT

- Density: 0.964 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 63

- Tensile Strength, Yield: 27.0 MPa

$ 1650/MT

- Density: 1.12 g/cc

- Linear Mold Shrinkage: 0.0020 cm/cm

- Linear Mold Shrinkage: 0.011 cm/cm

- Melt Flow: 2.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 112 MPa

$ 2429/MT

- Density: 1.05 g/cc

- Linear Mold Shrinkage: 0.0010 cm/cm

- Linear Mold Shrinkage: 0.0065 cm/cm

- Melt Flow: 13 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 30.0 MPa

$ 1542/MT

- Density: 0.963 g/cc

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 64

- Tensile Strength at Break: 33.0 MPa

- Elongation at Break: 600 %

$ 1498/MT

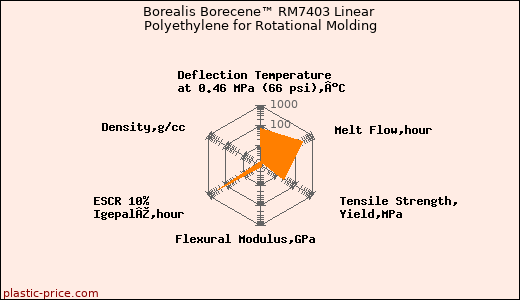

- Bulk Density: 0.500 - 0.600 g/cc

- Density: 0.943 g/cc

- Density: 0.945 g/cc

- Thermal Stress Crack Resistance: 1.50 hour @Temperature 105 °C

- Oxidative Induction Time (OIT): >= 50 min @Temperature 200 °C

$ 2060/MT

- Density: 0.919 g/cc

- Molecular Weight: 133000 g/mol

- Melt Flow: 1.2 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength, Yield: 12.0 MPa

- Film Elongation at Break, MD: 740 %

$ 2382/MT

- Density: 0.954 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 4.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 61

- Tensile Strength, Yield: 24.0 MPa

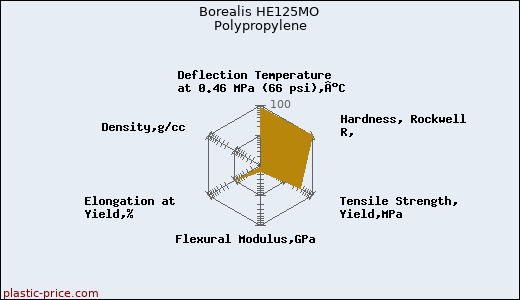

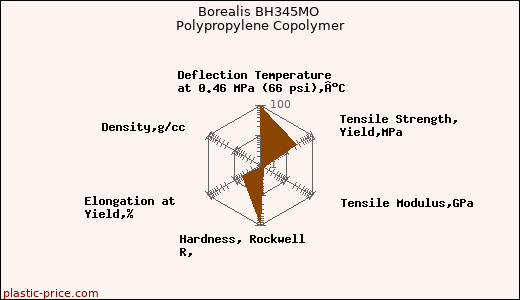

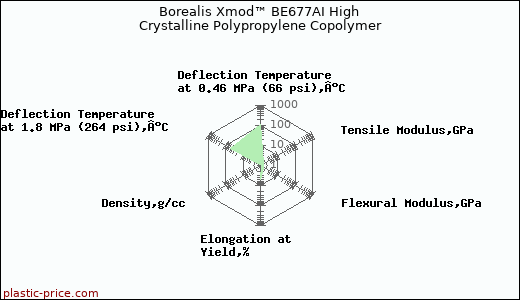

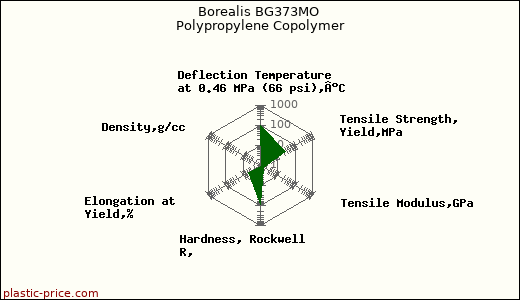

$ 1973/MT

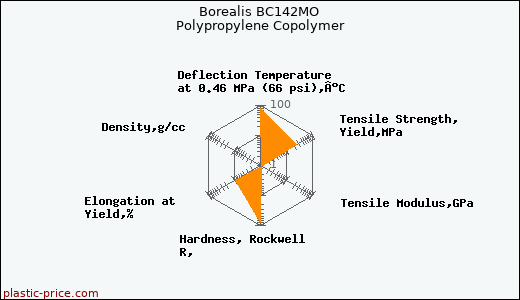

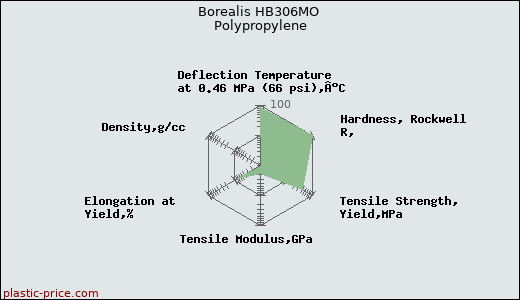

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 7.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 89

- Tensile Strength, Yield: 27.0 MPa

- Elongation at Yield: 4.5 %

$ 2174/MT

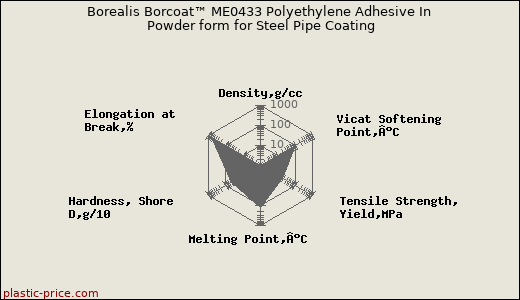

- Density: 1.15 g/cc

- Melt Flow: 0.40 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 39

- Tensile Strength, Yield: >= 8.83 MPa

- Tensile Strength, Yield: 11.0 MPa

$ 2114/MT

- Density: 0.908 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 98

- Tensile Strength, Yield: 33.5 MPa

$ 1501/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 30 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 75

- Tensile Strength, Yield: 27.0 MPa

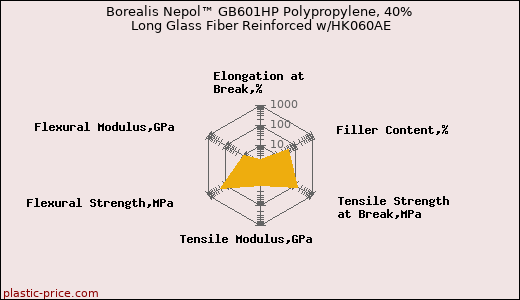

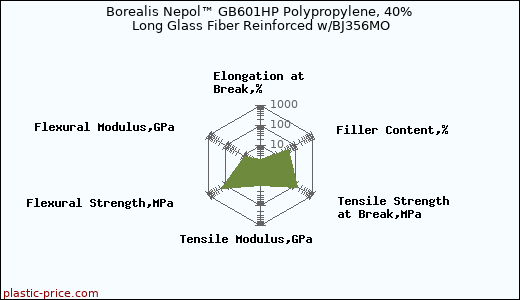

$ 1959/MT

- Filler Content: 40 %

- Tensile Strength at Break: 145 MPa

- Elongation at Break: 2.1 %

- Tensile Modulus: 10.0 GPa

- Flexural Strength: 195 MPa

$ 1730/MT

- Density: 0.950 g/cc

- Linear Mold Shrinkage: 0.0015 cm/cm

- Linear Mold Shrinkage: 0.0080 cm/cm

- Melt Flow: 25 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 23.0 MPa

$ 1699/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Film Elongation at Break, MD: 500 - 700 %

- Film Elongation at Break, TD: 500 - 700 %

- Tensile Modulus: 0.650 - 0.750 GPa

$ 1577/MT

- Density: 0.905 g/cc

- Melt Flow: 0.75 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 35.0 MPa

- Elongation at Yield: 10 %

- Tensile Modulus: 1.49 GPa

$ 1555/MT

- Density: 0.905 g/cc

- Melt Flow: 20 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 90

- Tensile Strength, Yield: 28.0 MPa

- Elongation at Yield: 12 %

$ 1818/MT

- Density: 0.927 g/cc

- Thickness: 40.0 microns

- Melt Flow: 2.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Antiblock Level: 750 ppm

- Film Elongation at Break, MD: 230 %

$ 2067/MT

- Density: 0.970 g/cc

- Linear Mold Shrinkage: 0.0015 cm/cm

- Linear Mold Shrinkage: 0.010 cm/cm

- Melt Flow: 9.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 33.0 MPa

$ 1984/MT

- Density: 0.923 g/cc

- Density: 1.05 g/cc

- Density: 2.00 g/cc

- Melt Flow: 0.90 g/10 min

- Tensile Strength, Yield: >= 14.58 MPa

$ 1702/MT

- Density: 1.10 g/cc

- Water Absorption: 0.030 %

- Tensile Strength at Break: <= 4.40 MPa

- Tensile Strength at Break: >= 22.0 MPa

- Elongation at Break: 380 %

$ 1459/MT

- Density: 0.905 g/cc

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 0.50 g/10 min @Load 5.00 kg, Temperature 190 °C

- Tensile Strength, Yield: 30.000 MPa

- Elongation at Yield: 10 %

$ 2233/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Slip Level: 2000 ppm

- Film Elongation at Break, MD: 500 - 700 %

- Film Elongation at Break, TD: 500 - 700 %

$ 2041/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 5.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 82

- Tensile Strength, Yield: 25.0 MPa

$ 1907/MT

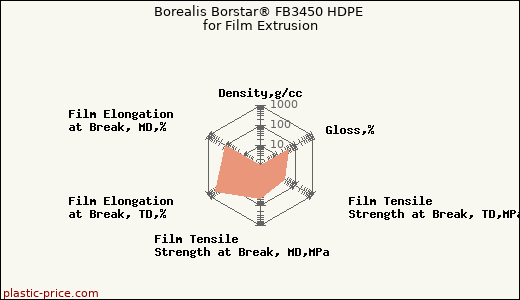

- Density: 0.956 g/cc

- Melt Flow: 0.30 g/10 min @Load 5.00 kg, Temperature 190 °C

- Melt Flow: 9.0 g/10 min @Load 21.6 kg, Temperature 190 °C

- Film Elongation at Break, MD: 250 %

- Film Elongation at Break, TD: 300 %

$ 1593/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 7.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Film Elongation at Break, MD: 600 - 800 %

- Film Elongation at Break, TD: 600 - 800 %

- Tensile Modulus: 0.450 - 0.550 GPa

$ 2191/MT

- Density: 0.900 g/cc

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 30.00 MPa

- Elongation at Yield: 10 %

- Tensile Modulus: 1.50 GPa

$ 1799/MT

- Density: 1.15 g/cc

- Linear Mold Shrinkage, Flow: <= 0.0020 cm/cm @Thickness 2.00 mm

- Linear Mold Shrinkage, Transverse: >= 0.010 cm/cm

- Melt Flow: 4.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Spiral Flow: 95.0 cm @Thickness 2.00 mm, Temperature 250 °C

$ 1655/MT

- Density: 0.900 - 0.910 g/cc

- Thickness: 50.0 microns

- Melt Flow: 9.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Film Elongation at Break, MD: 650 %

- Film Elongation at Break, TD: 850 %

$ 2355/MT

- Density: 0.910 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 45 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 85

- Tensile Strength, Yield: 26.0 MPa

$ 1472/MT

- Density: 0.923 g/cc

- Melt Flow: 0.75 g/10 min @Load 2.16 kg, Temperature 190 °C

- Film Elongation at Break, MD: 250 %

- Film Elongation at Break, TD: 550 %

- Tensile Modulus: 0.230 GPa

$ 1653/MT

- Density: 1.04 g/cc

- Linear Mold Shrinkage: 0.0060 cm/cm

- Melt Flow: 25 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 15.00 MPa

- Elongation at Yield: 6.0 %

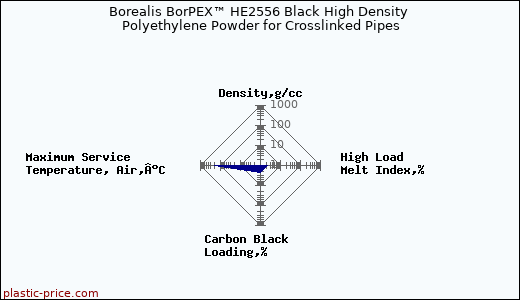

$ 2204/MT

- Density: 0.956 g/cc

- Density: 0.958 g/cc

- High Load Melt Index: 6.0 g/10 min @Load 21.6 kg, Temperature 190 °C

- Maximum Service Temperature, Air: 210 °C

$ 2112/MT

- Density: 1.07 g/cc

- Linear Mold Shrinkage: 0.010 cm/cm

- Melt Flow: 14 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 56 g/10 min @Load 5.00 kg, Temperature 230 °C

- Tensile Strength, Yield: 23.0 MPa

$ 1655/MT

- Density: 0.927 g/cc

- Melt Flow: 0.30 g/10 min @Load 5.00 kg, Temperature 190 °C

- Hardness, Shore D: 52

- Tensile Strength, Yield: 12.0 MPa

- Elongation at Break: 700 %

$ 1627/MT

- Density: 0.923 g/cc

- Environmental Stress Crack Resistance: >= 96 hour @Temperature 50.0 °C

- Melt Flow: 1.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 52

- Tensile Strength at Break: <= 11.25 MPa

$ 1997/MT

- Density: 1.15 g/cc

- Tensile Strength at Break: 9.90 MPa

- Tensile Strength at Break: 11.0 MPa

- Elongation at Break: >= 100 %

- Elongation at Break: 250 %

$ 2388/MT

- Density: 1.05 g/cc

- Linear Mold Shrinkage: 0.011 cm/cm

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 27.5 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 80.6 MPa

$ 1989/MT

- Melt Flow: 450 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melting Point: 161 - 165 °C

$ 1497/MT

- Density: 0.905 g/cc

- Melt Flow: 0.25 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 25.0 MPa

- Elongation at Yield: 13.5 %

- Tensile Modulus: 0.900 GPa

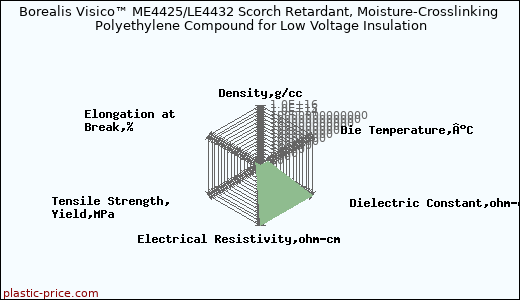

$ 2234/MT

- Density: 0.923 g/cc

- Density: 0.933 g/cc

- Melt Index of Compound: 0.90 g/10 min

- Tensile Strength, Yield: >= 13.28 MPa

- Tensile Strength, Yield: 14.8 MPa

$ 1462/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 19 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 93

- Tensile Strength, Yield: 29.5 MPa

$ 1898/MT

- Density: 1.04 g/cc

- Linear Mold Shrinkage: 0.011 cm/cm

- Melt Flow: 23 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 88 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 78.0 MPa

$ 1965/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Film Elongation at Break, MD: 400 - 500 %

- Tensile Modulus: 0.650 - 0.850 GPa

- Flexural Modulus: 0.700 GPa

$ 1479/MT

- Density: 0.956 g/cc

- Density: 0.959 g/cc

- High Load Melt Index: 6.0 g/10 min @Load 21.6 kg, Temperature 190 °C

- Maximum Service Temperature, Air: 210 °C

$ 1517/MT

- Melt Flow: 1200 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melting Point: 156 - 160 °C

$ 1703/MT

- Density: 0.922 g/cc

- Melt Flow: 1.2 g/10 min @Load 2.16 kg, Temperature 190 °C

- Antiblock Level: 850 ppm

- Film Elongation at Break, MD: 300 %

- Film Elongation at Break, TD: 500 %

$ 1730/MT

- Density: 0.958 g/cc

- ESCR 10% Igepal®: >= 100 hour

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 190 °C

- Melt Flow: 1.3 g/10 min @Load 5.00 kg, Temperature 190 °C

- High Load Melt Index: 28 g/10 min @Load 21.6 kg, Temperature 190 °C

$ 1527/MT

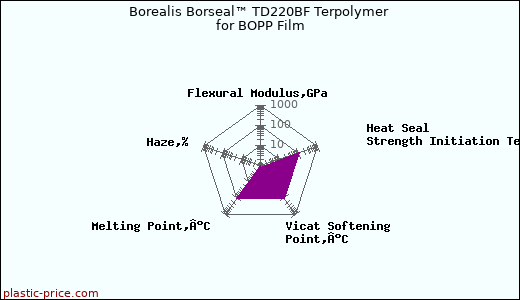

- Melt Flow: 6.5 g/10 min @Load 2.16 kg, Temperature 230 °C

- Flexural Modulus: 0.750 GPa

- Heat Seal Strength Initiation Temperature: 108 °C

- Melting Point: 130 - 134 °C

- Vicat Softening Point: 117 °C

- Haze: 1.8 %

$ 1813/MT

- Density: 0.922 g/cc

- Melt Flow: 2.1 g/10 min @Load 2.16 kg, Temperature 190 °C

- Antiblock Level: 850 ppm

- Slip Level: 500 ppm

- Film Elongation at Break, MD: 350 %

$ 1588/MT

- Density: 0.944 g/cc

- Environmental Stress Crack Resistance: >= 5.0 hour @Temperature 50.0 °C

- Melt Flow: 1.7 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 58

- Hardness, Shore D: 61

$ 2409/MT

- Density: 0.959 g/cc

- Environmental Stress Crack Resistance: 1.0 hour @Pressure 0.920 MPa, Temperature 80.0 °C

- Oxidative Induction Time (OIT): >= 20 min @Temperature 200 °C

- Carbon Black Loading: 2.0 %

- Melt Flow: 0.55 g/10 min @Load 5.00 kg, Temperature 190 °C

$ 1465/MT

- Density: 0.951 g/cc

- Oxidative Induction Time (OIT): >= 50 min @Temperature 210 °C

- Melt Flow: 10 g/10 min @Load 21.6 kg, Temperature 190 °C

- Tensile Strength, Yield: 22.0 MPa

$ 1520/MT

- Density: 0.945 g/cc

- Environmental Stress Crack Resistance: >= 80 hour @Temperature 50.0 °C

- Oxidative Induction Time (OIT): >= 60 min @Temperature 200 °C

- Melt Flow: 0.70 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 58

$ 1754/MT

- Bulk Density: 0.500 - 0.600 g/cc

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.015 cm/cm

- Melt Flow: 21 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 102

$ 1516/MT

- Density: 0.945 g/cc

- Environmental Stress Crack Resistance: >= 48 hour @Temperature 50.0 °C

- Oxidative Induction Time (OIT): 50 min @Temperature 200 °C

- Melt Flow: 0.70 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 61

$ 1827/MT

- Density: 0.942 g/cc

- Density: 0.954 g/cc

- ESCR 10% Igepal®: >= 2000 hour @Temperature 50.0 °C

- Melt Flow: 1.7 g/10 min

- Hardness, Shore D: 61

$ 1491/MT

- Density: 0.947 g/cc

- Melt Flow: 0.60 g/10 min @Load 2.16 kg, Temperature 190 °C

- Melting Point: 131 °C

- Molecular Weight: medium distribution

$ 1516/MT

- Density: 0.923 g/cc

- Density: 0.936 g/cc

- Environmental Stress Crack Resistance: >= 5.0 hour @Temperature 50.0 °C

- Melt Flow: 0.85 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 53

$ 1988/MT

- Density: 0.923 g/cc

- Water Vapor Transmission: 8.00 g/m²/day

- Oxygen Transmission Rate: 5000 cc/m²/day

- Thickness: 40.0 microns

- Melt Flow: 0.40 g/10 min @Load 2.16 kg, Temperature 190 °C

$ 1961/MT

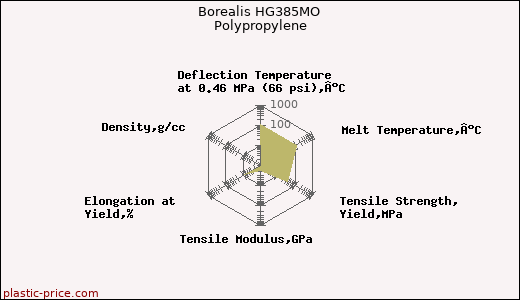

- Density: 0.920 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 20 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 112

- Tensile Strength, Yield: 40.00 MPa

$ 1445/MT

- Bulk Density: 0.500 - 0.600 g/cc

- Density: 0.902 g/cc

- Melt Flow: 1.9 g/10 min @Load 1.90 kg, Temperature 230 °C

- Tensile Strength, Yield: 26.0 MPa

- Elongation at Yield: 12 %

$ 1915/MT

- Density: 0.922 g/cc

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 190 °C

- Film Elongation at Break, MD: 400 %

- Film Elongation at Break, TD: 600 %

- Tensile Modulus: 0.190 GPa

$ 1578/MT

- Density: 1.24 g/cc

- Linear Mold Shrinkage: 0.0040 cm/cm

- Melt Flow: 2.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Elongation at Break: 2.0 %

- Tensile Modulus: 9.00 GPa

$ 1672/MT

- Density: 0.923 g/cc

- Density: 1.38 g/cc

- Melt Index of Compound: 0.90 g/10 min

- Tensile Strength, Yield: >= 13.28 MPa

- Tensile Strength, Yield: 14.8 MPa

$ 1737/MT

- Density: 0.905 g/cc

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 25.00 MPa

- Elongation at Yield: 10 %

- Modulus of Elasticity: 0.900 GPa

$ 1536/MT

- Density: 0.958 g/cc

- Water Vapor Transmission: 4.10 g/m²/day @Temperature 38.0 °C

- Oxygen Transmission Rate: 2210 cc/m²/day @Temperature 23.0 °C

- Molecular Weight: 130000 g/mol

- Melt Flow: 1.2 g/10 min @Load 2.16 kg, Temperature 190 °C

$ 1677/MT

- Melt Flow: 2.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 50

- Tensile Strength at Break: >= 13.5 MPa

- Tensile Strength at Break: 15.0 MPa

- Elongation at Break: 400 %

$ 1469/MT

- Melt Flow: 3.2 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 4.4 g/10 min @Load 5.00 kg, Temperature 190 °C

- Melt Flow: 14 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ash: 0.0010 - 0.0020 %

- Melting Point: 161 - 165 °C

$ 1696/MT

- Density: 0.920 g/cc

- Melt Flow: 20 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 90.0 MPa

- Tensile Strength, Yield: 41.0 MPa

- Tensile Modulus: 2.10 GPa

$ 1577/MT

- Density: 0.923 g/cc

- Density: 1.05 g/cc

- Melt Flow: 0.90 g/10 min

- Tensile Strength, Yield: >= 13.28 MPa

- Tensile Strength, Yield: 14.8 MPa

$ 1894/MT

- Density: 0.951 g/cc

- High Load Melt Index: 10 g/10 min @Load 21.6 kg, Temperature 190 °C

- Tensile Strength, Yield: 22.00 MPa

- Elongation at Break: >= 600 %

$ 2361/MT

- Density: 0.923 g/cc

- Density: 0.941 g/cc

- Melt Flow: 0.90 g/10 min

- Tensile Strength, Yield: >= 13.28 MPa

- Tensile Strength, Yield: 14.8 MPa

$ 1496/MT

- Density: 0.922 g/cc

- Water Absorption: 0.020 %

- Melt Flow: 2.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength at Break: <= 3.40 MPa

- Tensile Strength at Break: >= 17.0 MPa

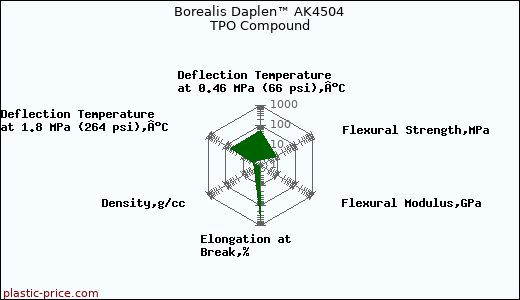

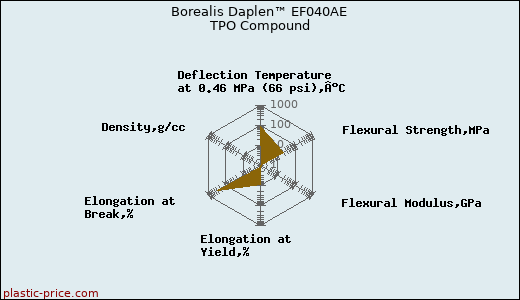

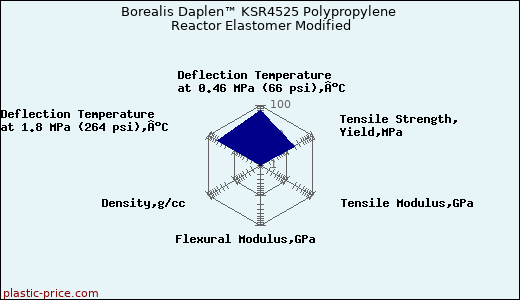

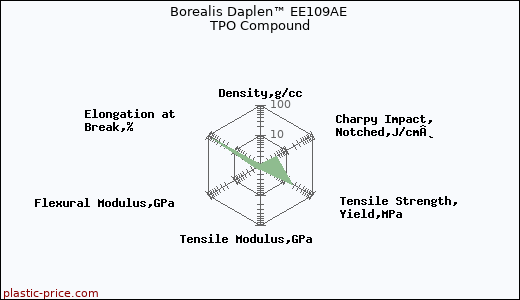

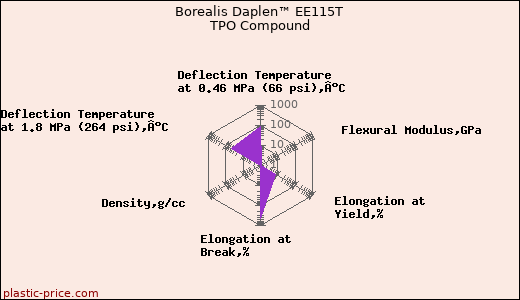

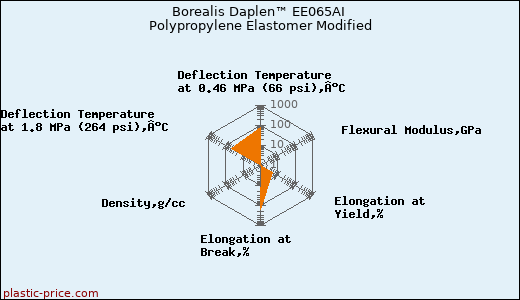

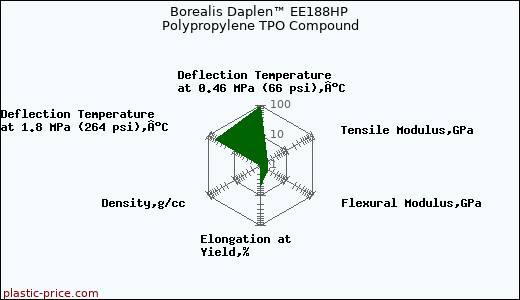

$ 2425/MT

- Melt Flow: 22 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 14.0 MPa

- Elongation at Yield: 15 %

- Tensile Modulus: 0.450 GPa

- Flexural Modulus: 0.400 GPa

$ 1446/MT

- Density: 1.03 g/cc

- Linear Mold Shrinkage: 0.010 cm/cm

- Melt Flow: 11 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 40 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 50.0 MPa

$ 1606/MT

- Density: 0.920 g/cc

- Melt Flow: 22 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 96 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 85.0 MPa

- Tensile Strength, Yield: 35.0 MPa

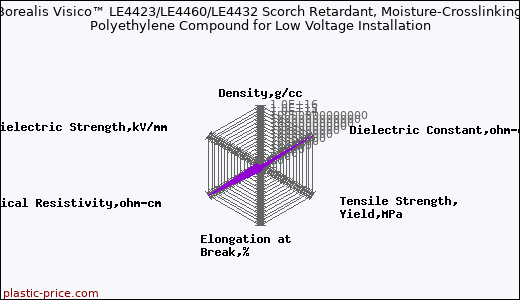

$ 2299/MT

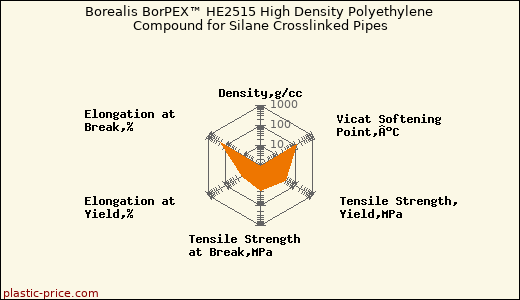

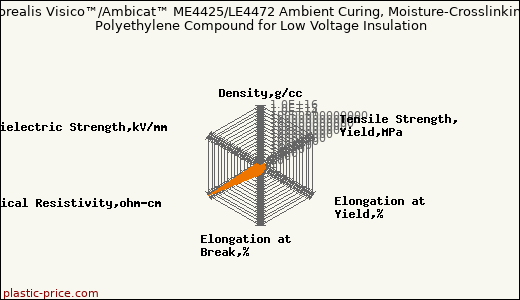

- Density: 0.923 g/cc

- Degree of Crosslinking: 12 %

- Hardness, Shore D: 50

- Tensile Strength, Yield: >= 14.3 MPa

- Tensile Strength, Yield: 15.9 MPa

$ 1562/MT

- Density: 0.905 g/cc

- Melt Flow: 30 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 90

- Tensile Strength, Yield: 27.50 MPa

- Elongation at Yield: 12 %

$ 1768/MT

- Bulk Density: 0.500 - 0.600 g/cc

- Density: 0.924 g/cc

- Water Absorption: 0.020 %

- Melt Flow: 2.8 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength at Break: <= 3.40 MPa

$ 2134/MT

- Density: 1.05 g/cc

- Linear Mold Shrinkage: 0.011 cm/cm

- Melt Flow: 12 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 49 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 62.0 MPa

$ 2031/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 45 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 80

- Tensile Strength, Yield: 27.0 MPa

$ 1766/MT

- Density: 1.22 g/cc

- Tensile Strength, Yield: >= 13.28 MPa

- Tensile Strength, Yield: 14.8 MPa

- Elongation at Break: 315 %

- Elongation at Break: 350 %

$ 1763/MT

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Flexural Modulus: 0.700 GPa

- Heat Seal Strength Initiation Temperature: 103 °C

- Melting Point: 128 - 132 °C

- Vicat Softening Point: 114 °C

$ 2162/MT

- Density: 1.12 g/cc

- Linear Mold Shrinkage: 0.0020 cm/cm

- Linear Mold Shrinkage: 0.010 cm/cm

- Melt Flow: 2.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 124 MPa

$ 1449/MT

- Density: 0.956 g/cc

- Density: 0.966 g/cc

- Carbon Black Loading: 2.2 %

- High Load Melt Index: 6.0 g/10 min @Load 21.6 kg, Temperature 190 °C

- Maximum Service Temperature, Air: 210 °C

$ 1452/MT

- Density: 1.12 g/cc

- Tensile Strength, Yield: >= 4.65 MPa

- Tensile Strength, Yield: 18.6 MPa

- Elongation at Break: 180 %

- Tensile Set: 45 %

$ 1453/MT

- Density: 1.07 g/cc

- Linear Mold Shrinkage: 0.0090 cm/cm

- Melt Flow: 13 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 22.99 MPa

- Elongation at Yield: 5.1 %

$ 1958/MT

- Density: 0.954 g/cc

- Environmental Stress Crack Resistance: 500 hour

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 190 °C

- Melt Flow: 1.5 g/10 min @Load 5.00 kg, Temperature 190 °C

- Melt Flow: 32 g/10 min @Load 21.6 kg, Temperature 190 °C

$ 1517/MT

- Density: 0.990 g/cc

- Linear Mold Shrinkage: 0.0090 cm/cm

- Melt Flow: 16 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 31.0 MPa

- Tensile Strength, Yield: 16.0 MPa

$ 1498/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.015 cm/cm

- Melt Flow: 15 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 70

- Tensile Strength, Yield: 20.99 MPa

$ 1597/MT

- Density: 0.923 g/cc

- Density: 1.38 g/cc

- Melt Index of Compound: 0.90 g/10 min

- Tensile Strength, Yield: >= 13.28 MPa

- Tensile Strength, Yield: 14.8 MPa

$ 1581/MT

- Density: 0.934 g/cc

- ESCR 10% Igepal®: >= 300 hour

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength, Yield: 17.9 MPa

- Flexural Modulus: 0.490 GPa

$ 1651/MT

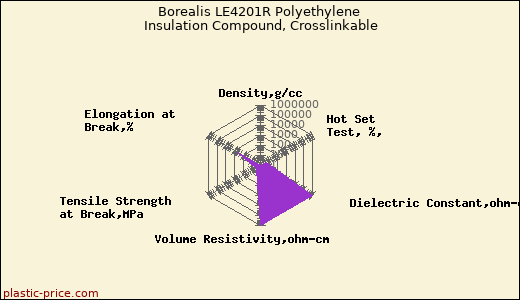

- Density: 1.17 g/cc

- Volume Resistivity: 50 ohm-cm @Temperature 23.0 °C

- Volume Resistivity: 90 ohm-cm @Temperature 90.0 °C

- Shelf Life: 12.0 Month

$ 1589/MT

- Density: 1.14 g/cc

- Water Absorption: 0.050 %

- Melt Flow: 10 g/10 min @Load 21.6 kg, Temperature 190 °C

- Hardness, Shore D: 56

- Tensile Strength at Break: 12.0 MPa

$ 1618/MT

- Density: 0.922 g/cc

- Water Absorption: 0.020 %

- Melt Flow: 2.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength at Break: <= 3.40 MPa

- Tensile Strength at Break: >= 17.0 MPa

$ 1768/MT

- Density: 1.04 g/cc

- Linear Mold Shrinkage: 0.0060 cm/cm

- Melt Flow: 14 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 32.0 MPa

- Tensile Strength at Break: 12.0 MPa

$ 1734/MT

- Density: 0.930 g/cc

- Density: 0.933 g/cc

- Melt Index of Compound: 0.70 g/10 min

- Tensile Strength, Yield: >= 18.6 MPa

- Tensile Strength, Yield: 20.7 MPa

$ 1799/MT

- Density: 1.04 g/cc

- Linear Mold Shrinkage: 0.0060 cm/cm

- Melt Flow: 14 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 32.0 MPa

- Tensile Strength at Break: 12.0 MPa

$ 1808/MT

- Density: 0.962 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 12 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 62

- Tensile Strength, Yield: 26.0 MPa

$ 2071/MT

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Flexural Modulus: 0.700 GPa

- Heat Seal Strength Initiation Temperature: 103 °C

- Melting Point: 128 - 132 °C

- Vicat Softening Point: 114 °C

- Haze: 1.0 %

$ 2110/MT

- Density: 0.930 g/cc

- Density: 1.05 g/cc

- Melt Flow: 0.70 g/10 min

- Tensile Strength, Yield: >= 18.6 MPa

- Tensile Strength, Yield: 20.7 MPa

$ 1785/MT

- Melt Flow: 3.2 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 4.5 g/10 min @Load 5.00 kg, Temperature 190 °C

- Melt Flow: 15 g/10 min @Load 5.00 kg, Temperature 230 °C

- Film Elongation at Break, MD: 150 - 200 %

- Film Elongation at Break, TD: 50 - 90 %

$ 2496/MT

- Bulk Density: 0.500 - 0.600 g/cc

- Density: 0.922 g/cc

- Water Absorption: 0.020 %

- Melt Flow: 2.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength at Break: <= 3.40 MPa

$ 1590/MT

- Melt Flow: 3.2 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 4.4 g/10 min @Load 5.00 kg, Temperature 190 °C

- Melt Flow: 14 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ash: 0.0010 - 0.0020 %

- Melting Point: 161 - 165 °C

$ 1929/MT

- Density: 0.922 g/cc

- Melt Flow: 4.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Film Elongation at Break, MD: 400 %

- Film Elongation at Break, TD: 650 %

- Tensile Modulus: 0.180 GPa

$ 1787/MT

- Density: 0.923 g/cc

- Melt Flow: 0.75 g/10 min @Load 2.16 kg, Temperature 190 °C

- Slip Level: 550 ppm

- Film Elongation at Break, MD: 250 %

- Film Elongation at Break, TD: 550 %

$ 2053/MT

- Density: 1.12 g/cc

- Linear Mold Shrinkage: 0.0020 cm/cm

- Linear Mold Shrinkage: 0.011 cm/cm

- Melt Flow: 2.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 112 MPa

$ 1538/MT

- Density: 0.962 g/cc

- Linear Mold Shrinkage: 0.020 cm/cm

- Melt Flow: 12 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 62

- Tensile Strength, Yield: 26.0 MPa

$ 2195/MT

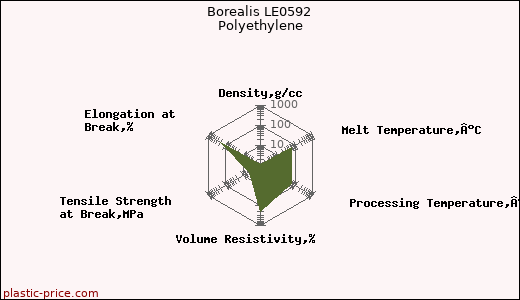

- Density: 1.15 g/cc

- Melt Flow: 5.2 g/10 min @Load 2.16 kg, Temperature 190 °C

$ 1481/MT

- Density: 0.980 g/cc

- Linear Mold Shrinkage: 0.0015 cm/cm

- Linear Mold Shrinkage: 0.0080 cm/cm

- Melt Flow: 40 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 28.0 MPa

$ 1462/MT

- Density: 0.902 g/cc

- Melt Flow: 13 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 86

- Tensile Strength, Yield: 25.0 MPa

- Elongation at Yield: 6.0 %

$ 1687/MT

- Density: 0.956 g/cc

- High Load Melt Index: 6.0 g/10 min @Load 21.6 kg, Temperature 190 °C

- Tensile Strength, Yield: 22.00 MPa

- Elongation at Break: >= 600 %

$ 1658/MT

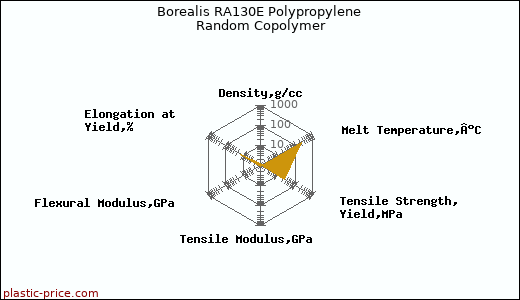

- Melt Flow: 2.4 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 40.00 MPa

- Elongation at Yield: 6.0 %

- Tensile Modulus: 1.95 GPa

- Flexural Modulus: 1.85 GPa

$ 1544/MT

- Density: 0.910 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 50 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 101

- Tensile Strength, Yield: 35.0 MPa

$ 1807/MT

- Density: 0.934 g/cc

- ESCR 10% Igepal®: >= 300 hour

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength, Yield: 17.9 MPa

- Flexural Modulus: 0.490 GPa

$ 1645/MT

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Flexural Modulus: 0.700 GPa

- Heat Seal Strength Initiation Temperature: 103 °C

- Melting Point: 128 - 132 °C

- Vicat Softening Point: 114 °C

- Haze: 1.0 %

$ 2484/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Antiblock Level: 1800 ppm

- Slip Level: 2100 ppm

- Film Elongation at Break, MD: 550 - 750 %

$ 1500/MT

- Density: 0.944 g/cc

- Density: 0.946 g/cc

- High Load Melt Index: 8.5 g/10 min @Load 21.6 kg, Temperature 190 °C

- Tensile Strength, Yield: 18.00 MPa

- Elongation at Break: >= 600 %

$ 1658/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.015 cm/cm

- Melt Flow: 125 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 78.0 MPa

- Tensile Strength, Yield: 35.0 MPa

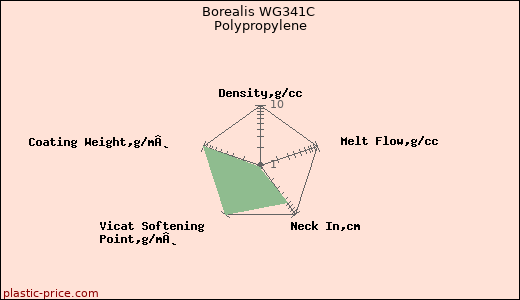

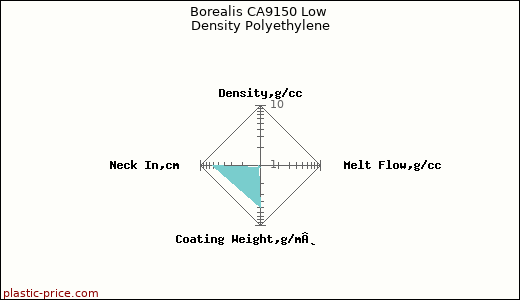

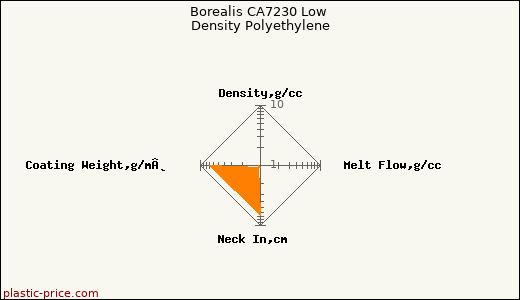

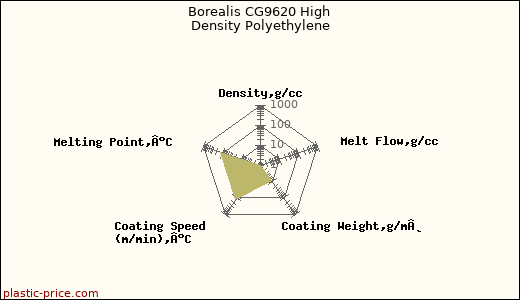

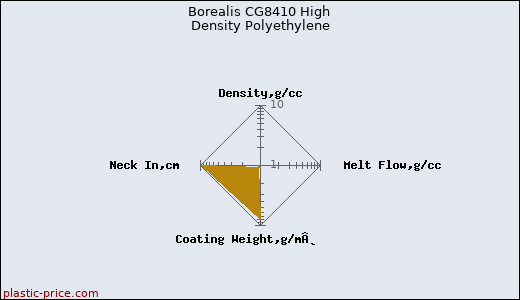

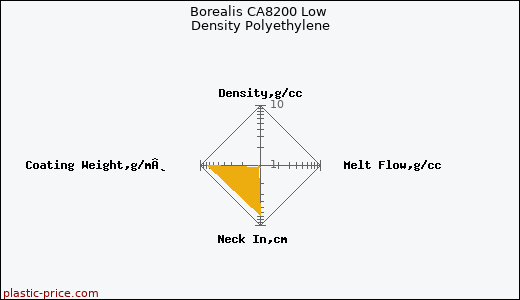

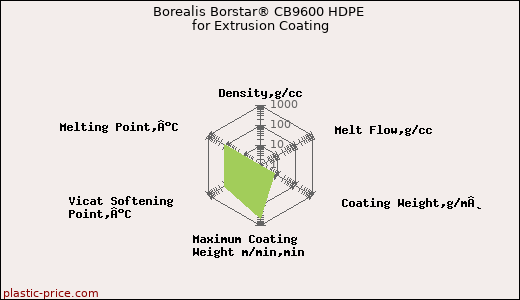

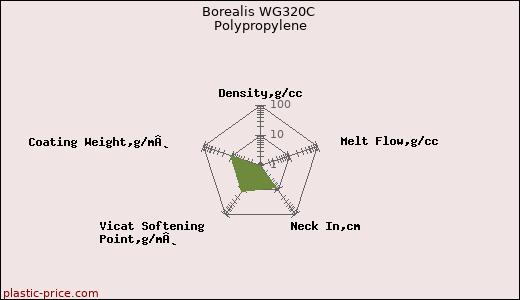

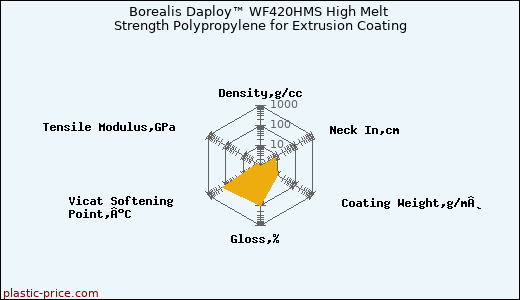

$ 1444/MT

- Density: 0.910 g/cc

- Melt Flow: 25 g/10 min @Load 2.16 kg, Temperature 230 °C

- Neck In: 5.80 cm

- Coating Weight: >= 10.0 g/m²

- Vicat Softening Point: 132 °C @Load 1.02 kg

$ 1657/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Film Elongation at Break, MD: 550 - 750 %

- Tensile Modulus: 0.350 - 0.450 GPa

- Flexural Modulus: 0.650 GPa

$ 2088/MT

- Density: 0.900 g/cc

- Melt Flow: 0.90 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Shore D: 62

- Tensile Strength, Yield: 25.0 MPa

- Elongation at Break: >= 100 %

$ 1820/MT

- Density: 0.900 g/cc

- Melt Flow: 0.50 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 29.0 MPa

- Elongation at Yield: 10 %

- Flexural Modulus: 1.50 GPa

$ 1762/MT

- Density: 0.980 g/cc

- Linear Mold Shrinkage: 0.00090 cm/cm

- Linear Mold Shrinkage: 0.0090 cm/cm

- Melt Flow: 11 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 23.0 MPa

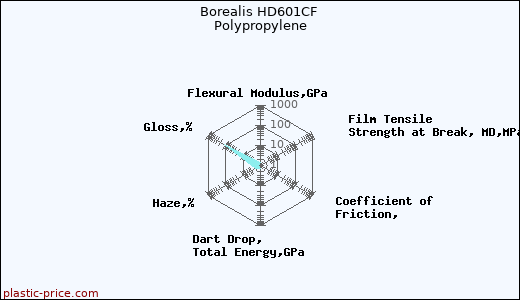

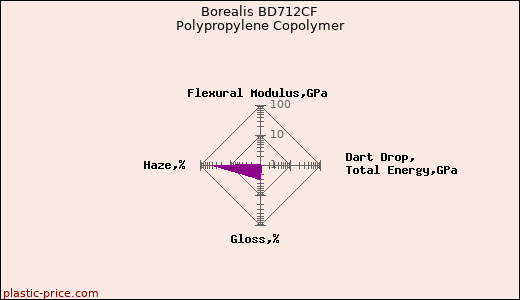

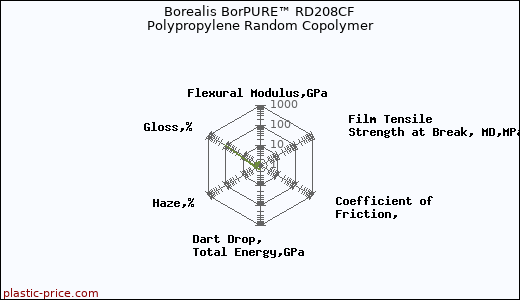

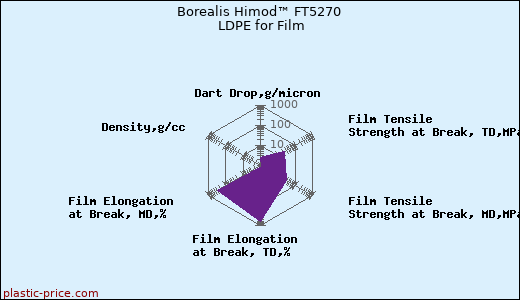

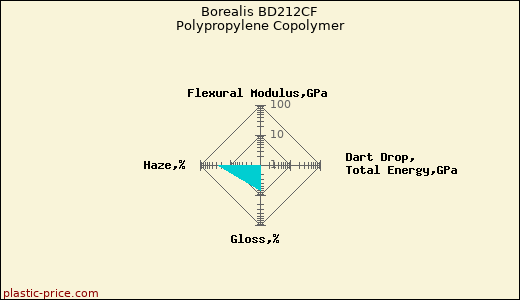

$ 1522/MT

- Density: 0.905 g/cc

- Melt Flow: 12 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Modulus: 0.500 GPa

- Flexural Modulus: 0.900 GPa

- Dart Drop, Total Energy: 20.0 J @Thickness 0.0500 mm

$ 1619/MT

- Density: 0.915 g/cc

- Melt Flow: 15 g/10 min @Load 2.16 kg, Temperature 190 °C

- Neck In: 6.30 cm

- Coating Weight: >= 5.00 g/m²

- Coating Speed (m/min): < 650

$ 1808/MT

- Density: 0.927 g/cc

- Thickness: 40.0 microns

- Melt Flow: 0.75 g/10 min @Load 2.16 kg, Temperature 190 °C

- Film Elongation at Break, MD: 300 %

- Film Elongation at Break, TD: 600 %

$ 1688/MT

- Density: 1.12 g/cc

- Linear Mold Shrinkage: 0.0020 cm/cm

- Linear Mold Shrinkage: 0.0090 cm/cm

- Melt Flow: 10 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 121 MPa

$ 1503/MT

- Density: 0.957 g/cc

- Environmental Stress Crack Resistance: 40 hour

- Melt Flow: 0.20 g/10 min @Load 2.16 kg, Temperature 190 °C

- Melt Flow: 1.0 g/10 min @Load 5.00 kg, Temperature 190 °C

- Melt Flow: 23 g/10 min @Load 21.6 kg, Temperature 190 °C

$ 2065/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 25 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 67

- Tensile Strength, Yield: 23.0 MPa

$ 1843/MT

- Density: 0.920 g/cc

- Melt Flow: 0.80 g/10 min @Load 2.16 kg, Temperature 190 °C

- Degree of Crosslinking: 12 %

- Hardness, Shore D: 52

- Tensile Strength, Yield: 17.2 MPa

$ 1534/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 18 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 89

- Tensile Strength, Yield: 26.0 MPa

$ 1923/MT

- Density: 0.923 g/cc

- Melt Flow: 4.5 g/10 min @Load 2.16 kg, Temperature 190 °C

- Neck In: 6.80 cm

- Coating Weight: >= 7.00 g/m²

- Coating Speed (m/min): < 700

$ 1699/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 70 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 88

- Tensile Strength, Yield: 30.0 MPa

$ 1454/MT

- Density: 0.962 g/cc

- Melt Flow: 12 g/10 min @Load 2.16 kg, Temperature 190 °C

- Coating Weight: 9.00 g/m²

- Melting Point: 131 °C

- Coating Speed (m/min): > 400 m/min

$ 1863/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Film Elongation at Break, MD: 80 %

- Film Elongation at Break, TD: 120 %

- Flexural Modulus: 2.10 GPa

$ 1768/MT

- Density: 0.934 g/cc

- Melt Flow: 4.0 - 6.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 47

- Tensile Strength, Yield: 18.00 MPa

- Elongation at Break: >= 700 %

$ 2241/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Antiblock Level: 1800 ppm

- Slip Level: 2000 ppm

- Film Elongation at Break, MD: 500 - 700 %

$ 1601/MT

- Density: 0.900 g/cc

- Melt Flow: 16 g/10 min @Load 2.16 kg, Temperature 230 °C

- Neck In: 11.0 cm

- Coating Weight: 12.0 g/m²

- Tensile Modulus: 0.850 GPa

$ 1912/MT

- Density: 0.965 g/cc

- Environmental Stress Crack Resistance: 15 hour

- Melt Flow: 0.70 g/10 min @Load 2.16 kg, Temperature 190 °C

- Melt Flow: 60 g/10 min @Load 21.6 kg, Temperature 190 °C

- Tensile Strength, Yield: 32.0 MPa

$ 1974/MT

- Density: 1.04 g/cc

- Linear Mold Shrinkage: 0.011 cm/cm

- Melt Flow: 16 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 61.0 MPa

- Tensile Strength at Break: 10.0 MPa

$ 1509/MT

- Density: 0.910 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 35 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 102

- Tensile Strength, Yield: 36.0 MPa

$ 1520/MT

- Melt Flow: 2.5 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 30.0 MPa

- Elongation at Yield: 6.0 %

- Tensile Modulus: 2.40 GPa

- Flexural Strength: 40.0 MPa

$ 2515/MT

- Density: 0.943 g/cc

- Melt Flow: 0.85 g/10 min

$ 1755/MT

- Density: 0.924 g/cc

- Water Absorption: 0.020 %

- Melt Flow: 2.4 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength at Break: <= 3.40 MPa

- Tensile Strength at Break: >= 17.0 MPa

$ 1527/MT

- Density: 1.40 g/cc

- Hardness, Shore D: 50

- Tensile Strength at Break: 12.8 MPa

- Tensile Strength at Break: 16.0 MPa

- Elongation at Break: 220 %

$ 1597/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 1.2 g/10 min @Load 2.16 kg, Temperature 230 °C

- Film Elongation at Break, MD: 550 - 750 %

- Film Elongation at Break, TD: 550 - 750 %

- Tensile Modulus: 0.500 - 0.600 GPa

$ 2511/MT

- Density: 0.900 g/cc

- Density: 0.920 g/cc

- Melt Flow: 0.90 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Shore D: 62

- Tensile Strength, Yield: 25.0 MPa

$ 1674/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.015 - 0.020 cm/cm

- Melt Flow: 20 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 89

- Tensile Strength, Yield: 27.00 MPa

$ 1451/MT

- Melt Flow: 37 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melting Point: 161 - 165 °C

- Molecular Weight: narrow distribution

$ 2392/MT

- Density: 0.930 g/cc

- Melt Flow: 0.30 g/10 min @Load 5.00 kg, Temperature 190 °C

- Hardness, Shore D: 53

- Tensile Strength, Yield: 14.0 MPa

- Tensile Modulus: 0.400 GPa

$ 1641/MT

- Density: 1.03 g/cc

- Linear Mold Shrinkage: 0.010 cm/cm

- Melt Flow: 11 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 40 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 50.0 MPa

$ 1832/MT

- Density: 1.40 g/cc

- Hardness, Shore D: 48

- Tensile Strength at Break: 9.00 MPa

- Elongation at Break: 280 %

- Volume Resistivity: 1.00e+6 ohm-cm

$ 1954/MT

- Density: 0.955 g/cc

- High Load Melt Index: 3.0 g/10 min @Load 21.6 kg, Temperature 190 °C

- Tensile Strength, Yield: 22.00 MPa

- Elongation at Break: >= 600 %

$ 1888/MT

- Density: 1.13 g/cc

- Tensile Strength, Yield: >= 7.24 MPa

- Tensile Strength, Yield: 14.5 MPa

- Elongation at Break: 200 %

- Tensile Set: >= 100 %

$ 1948/MT

- Density: 0.905 g/cc

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Modulus: 0.400 GPa

- Flexural Modulus: 0.700 GPa

- Dart Drop, Total Energy: 30.0 J @Thickness 0.0500 mm

$ 1489/MT

- Density: 1.02 g/cc

- Linear Mold Shrinkage: 0.0090 cm/cm

- Melt Flow: 26 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 49.0 MPa

- Tensile Strength, Yield: 22.0 MPa

$ 1576/MT

- Density: 0.906 g/cc

- Melt Flow: 30 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 27.0 MPa

- Elongation at Yield: 13 %

- Tensile Modulus: 1.05 GPa

$ 2133/MT

- Density: 0.950 g/cc

- Linear Mold Shrinkage: 0.0080 cm/cm

- Melt Flow: 12 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 16.0 MPa

- Elongation at Break: 400 %

$ 1762/MT

- Density: 0.910 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 55 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 107

- Tensile Strength, Yield: 38.0 MPa

$ 2394/MT

- Density: 0.902 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 13 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 86

- Tensile Strength, Yield: 25.0 MPa

$ 1456/MT

- Density: 0.900 g/cc

- Melt Flow: 3.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Shore D: 53

- Tensile Strength, Yield: 18.0 MPa

- Elongation at Yield: 10 %

$ 1873/MT

- Density: 0.918 g/cc

- Density: 0.931 g/cc

- Environmental Stress Crack Resistance: >= 1000 hour @Temperature 50.0 °C

- Melt Flow: 0.20 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 50

$ 2251/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 11 g/10 min @Load 2.16 kg, Temperature 230 °C

- Film Elongation at Break, MD: 550 - 750 %

- Tensile Modulus: 0.400 - 0.500 GPa

- Flexural Modulus: 0.800 GPa

$ 2430/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Antiblock Level: 1800 ppm

- Slip Level: 1000 ppm

- Film Elongation at Break, MD: 550 - 750 %

$ 2143/MT

- Density: 0.934 g/cc

- ESCR 10% Igepal®: >= 300 hour

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength, Yield: 17.9 MPa

- Flexural Modulus: 0.490 GPa

$ 1940/MT

- Density: 0.905 g/cc

- Melt Flow: 2.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 33.5 MPa

- Elongation at Yield: 10 %

- Tensile Modulus: 1.40 GPa

$ 1475/MT

- Density: 0.960 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 31 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 62

- Tensile Strength, Yield: 25.0 MPa

$ 2174/MT

- Density: 0.902 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 20 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 112

- Tensile Strength, Yield: 40.0 MPa

$ 1603/MT

- Density: 0.922 g/cc

- Melt Flow: 0.30 g/10 min @Load 5.00 kg, Temperature 190 °C

- Hardness, Shore D: 49

- Tensile Strength, Yield: 10.0 MPa

- Elongation at Break: 700 %

$ 1622/MT

- Melt Flow: 6.5 g/10 min @Load 2.16 kg, Temperature 230 °C

- Flexural Modulus: 0.700 GPa

- Heat Seal Strength Initiation Temperature: 103 °C

- Melting Point: 128 - 132 °C

- Vicat Softening Point: 114 °C

- Haze: 1.8 %

$ 2118/MT

- Density: 1.04 g/cc

- Tensile Strength, Yield: >= 17.69 MPa

- Tensile Strength, Yield: 19.7 MPa

- Elongation at Break: 472.5 %

- Elongation at Break: 525 %

$ 1848/MT

- Density: 0.922 g/cc

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 190 °C

- Film Elongation at Break, MD: 400 %

- Film Elongation at Break, TD: 600 %

- Tensile Modulus: 0.190 GPa

$ 1986/MT

- Density: 0.918 g/cc

- Environmental Stress Crack Resistance: >= 96 hour @Temperature 50.0 °C

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 50

- Tensile Strength at Break: 15.0 MPa

$ 1988/MT

- Density: 0.921 g/cc

- Density: 0.933 g/cc

- Environmental Stress Crack Resistance: >= 2500 hour @Temperature 50.0 °C

- Melt Flow: 0.35 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 50

$ 2224/MT

- Density: 0.900 g/cc

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Shore D: 59

- Tensile Strength, Yield: 18.0 MPa

- Elongation at Yield: 4.0 %

$ 1495/MT

- Bulk Density: 0.500 - 0.600 g/cc

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 11 g/10 min @Load 2.16 kg, Temperature 230 °C

- Slip Level: 2000 ppm

- Film Elongation at Break, MD: 550 - 750 %

$ 1529/MT

- Density: 0.910 g/cc

- Linear Mold Shrinkage: 0.0095 cm/cm

- Melt Flow: 22 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 18.0 MPa

- Elongation at Break: 330 %

$ 1481/MT

- Density: 0.905 g/cc

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 25.0 MPa

- Elongation at Yield: 13.5 %

- Tensile Modulus: 0.900 GPa

$ 1882/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 20 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 29.0 MPa

- Elongation at Yield: 11 %

$ 2046/MT

- Density: 0.929 g/cc

- Thickness: 40.0 microns

- Melt Flow: 3.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Antiblock Level: 550 ppm

- Film Elongation at Break, MD: 250 %

$ 2259/MT

- Density: 0.905 g/cc

- Melt Flow: 20 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 90

- Tensile Strength, Yield: 28.0 MPa

- Elongation at Yield: 12 %

$ 1472/MT

- Density: 0.932 g/cc

- Thickness: 40.0 microns

- Melt Flow: 4.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Antiblock Level: 550 ppm

- Slip Level: 750 ppm

$ 1888/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 20 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 82

- Tensile Strength, Yield: 29.0 MPa

$ 1608/MT

- Density: 0.942 g/cc

- ESCR 10% Igepal®: >= 5000 hour

- Melt Flow: 0.50 g/10 min @Load 2.16 kg, Temperature 190 °C

- Melt Flow: 2.0 g/10 min @Load 5.00 kg, Temperature 190 °C

- Hardness, Shore D: 60

$ 1632/MT

- Melt Flow: 25 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melting Point: 161 - 165 °C

- Molecular Weight: narrow distribution

$ 1663/MT

- Water Absorption: 0.040 %

- Environmental Stress Crack Resistance: >= 2.0 hour @Temperature 50.0 °C

- Melt Flow: 25 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 45

- Tensile Strength at Break: 3.125 MPa

$ 1663/MT

- Melt Flow: 19 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melting Point: 161 - 165 °C

- Molecular Weight: narrow distribution

$ 2051/MT

- Density: 1.145 g/cc

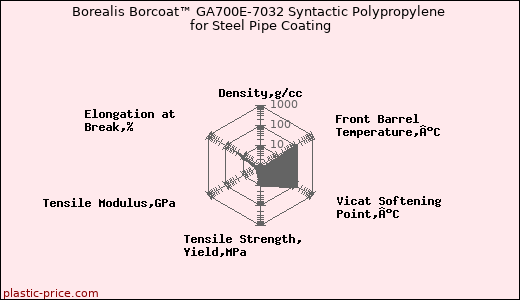

- Linear Mold Shrinkage: 0.0010 cm/cm

- Linear Mold Shrinkage: 0.0075 cm/cm

- Melt Flow: 15 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 63.0 MPa

$ 2177/MT

- Density: 0.934 g/cc

- ESCR 10% Igepal®: >= 4.0 hour

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 55

- Tensile Strength, Yield: 18.0 MPa

$ 2065/MT

- Density: 0.910 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 45 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 100

- Tensile Strength, Yield: 34.0 MPa

$ 2542/MT

- Density: 1.22 g/cc

- Tensile Strength at Break: >= 11.8 MPa

- Tensile Strength at Break: 13.1 MPa

- Elongation at Break: 275 %

- Oxygen Index: 27 %

$ 1528/MT

- Density: 0.990 g/cc

- Linear Mold Shrinkage: 0.0090 cm/cm

- Melt Flow: 10 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 35.0 MPa

- Tensile Strength, Yield: 17.00 MPa

$ 1664/MT

- Density: 0.905 g/cc

- Melt Flow: 4.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Modulus: 0.330 GPa

- Flexural Modulus: 0.550 GPa

- Dart Drop, Total Energy: 15.0 J

$ 1538/MT

- Density: 1.05 g/cc

- Linear Mold Shrinkage: 0.011 cm/cm

- Melt Flow: 12 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 60 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 88.5 MPa

$ 1990/MT

- Density: 0.904 g/cc

- Melt Flow: 90 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 25.0 MPa

- Elongation at Break: 10 %

- Tensile Modulus: 1.30 GPa

$ 1703/MT

- Density: 0.902 g/cc

- Melt Flow: 1.9 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 26.2 MPa

- Elongation at Yield: 13 %

- Tensile Modulus: 1.00 GPa

$ 2425/MT

- Density: 0.905 g/cc

- Melt Flow: 2.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 34.5 MPa

- Elongation at Yield: 9.0 %

- Tensile Modulus: 1.70 GPa

$ 1638/MT

- Density: 1.04 g/cc

- Linear Mold Shrinkage: 0.0020 cm/cm

- Linear Mold Shrinkage: 0.011 cm/cm

- Melt Flow: 2.2 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 101 MPa

$ 2035/MT

- Density: 0.910 g/cc

- Melt Flow: 96 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 66.0 MPa

- Tensile Strength, Yield: 26.0 MPa

- Elongation at Yield: 6.0 %

$ 1448/MT

- Density: 0.948 g/cc

- Environmental Stress Crack Resistance: 300 hour

- Melt Flow: 7.0 g/10 min @Load 21.6 kg, Temperature 190 °C

- Hardness, Shore D: 62

- Tensile Strength, Yield: 24.0 MPa

$ 2489/MT

- Density: 0.950 g/cc

- Linear Mold Shrinkage: 0.010 cm/cm

- Melt Flow: 12 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 18.0 MPa

- Elongation at Break: 60 %

$ 1624/MT

- Density: 0.934 g/cc

- Melt Flow: 1.3 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 47

- Tensile Strength, Yield: 18.0 MPa

- Elongation at Break: >= 700 %

$ 2104/MT

- Density: 0.905 g/cc

- Melt Flow: 2.8 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 35.0 MPa

- Elongation at Yield: 9.0 %

- Tensile Modulus: 1.60 GPa

$ 2084/MT

- Density: 1.04 g/cc

- Linear Mold Shrinkage, Flow: 0.0090 cm/cm

- Linear Mold Shrinkage, Transverse: 0.010 cm/cm

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 26 g/10 min @Load 5.00 kg, Temperature 230 °C

$ 1673/MT

- Density: 0.941 g/cc

- Melt Flow: 7.5 g/10 min @Load 2.16 kg, Temperature 190 °C

- Neck In: 9.50 cm

- Coating Weight: >= 8.00 g/m²

- Coating Speed (m/min): < 500

$ 1729/MT

- Density: 1.12 g/cc

- Linear Mold Shrinkage: 0.0060 cm/cm

- Melt Flow: 20 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 16.0 MPa

- Elongation at Break: 123 %

$ 1666/MT

- Melt Flow: 12 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melting Point: 161 - 165 °C

- Molecular Weight: medium distribution

$ 1524/MT

- Density: 1.13 g/cc

- Water Absorption: 0.080 %

- Tensile Strength at Break: 15.0 MPa

- Elongation at Break: 400 %

- Volume Resistivity: <= 100 ohm-cm @Temperature 23.0 °C

$ 1851/MT

- Density: 0.920 g/cc

- Melt Flow: 7.5 g/10 min @Load 2.16 kg, Temperature 190 °C

- Neck In: 6.80 cm

- Coating Weight: >= 7.50 g/m²

- Coating Speed (m/min): < 850

$ 2420/MT

- Density: 0.900 - 0.910 g/cc

- Thickness: 50.0 microns

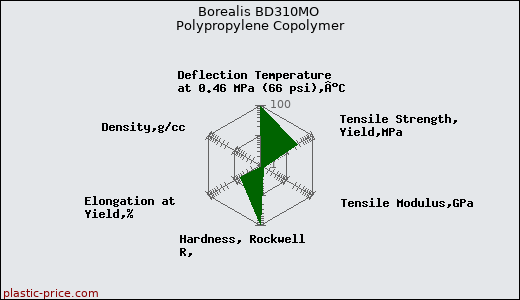

- Melt Flow: 10 g/10 min @Load 2.16 kg, Temperature 230 °C

- Film Elongation at Break, MD: 650 %

- Film Elongation at Break, TD: 850 %

$ 1725/MT

- Density: 1.135 g/cc

- Water Absorption: 0.030 %

- Tensile Strength at Break: <= 4.40 MPa

- Tensile Strength at Break: 22.0 MPa

- Elongation at Break: 200 %

$ 2321/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 20 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 82

- Tensile Strength, Yield: 29.0 MPa

$ 1743/MT

- Density: 1.135 g/cc

- Water Absorption: 0.060 %

- Tensile Strength at Break: <= 2.20 MPa

- Tensile Strength at Break: 11.0 MPa

- Elongation at Break: 200 %

$ 1910/MT

- Density: 0.905 g/cc

- Melt Flow: 0.25 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 25.0 MPa

- Elongation at Yield: 13.5 %

- Tensile Modulus: 0.900 GPa

$ 1835/MT

- Melt Flow: 3.0 g/10 min

- Tensile Strength, Yield: 30.0 MPa

- Tensile Modulus: 1.00 GPa

- Charpy Impact, Notched: 0.400 J/cm² @Temperature 0.000 °C

- Charpy Impact, Notched: 1.50 J/cm² @Temperature 23.0 °C

$ 1593/MT

- Density: 1.14 g/cc

- Tensile Strength, Yield: >= 11.0 MPa

- Tensile Strength, Yield: 22.1 MPa

- Elongation at Break: 200 %

- Tensile Set: >= 100 %

$ 1559/MT

- Density: 1.16 g/cc

- Melt Flow: 0.60 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 53

- Tensile Strength at Break: 2.25 MPa

- Tensile Strength at Break: 15.0 MPa

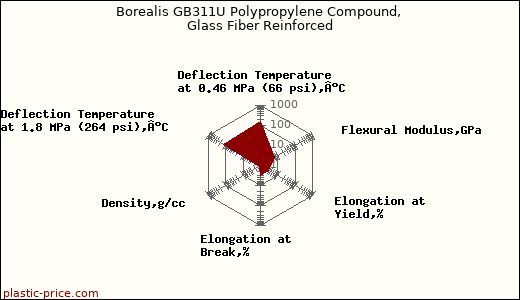

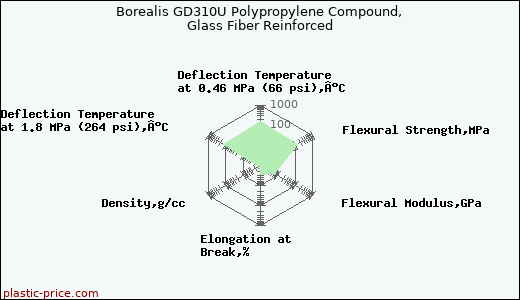

$ 2382/MT

- Density: 1.18 g/cc

- Linear Mold Shrinkage: 0.0010 - 0.0020 cm/cm

- Linear Mold Shrinkage: 0.0080 - 0.012 cm/cm

- Melt Flow: 2.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength at Break: 118 MPa

$ 1547/MT

- Density: 0.951 g/cc

- Environmental Stress Crack Resistance: >= 1000 hour @Temperature 80.0 °C

- Melt Flow: 0.30 g/10 min @Load 5.00 kg, Temperature 190 °C

- Tensile Strength, Yield: 24.99 MPa

- Elongation at Break: >= 600 %

$ 1457/MT

- Density: 0.958 g/cc

- Melt Flow: 0.60 g/10 min @Load 2.16 kg, Temperature 190 °C

- Melting Point: 131 °C

$ 1913/MT

- Density: 0.910 g/cc

- Melt Flow: 6.5 g/10 min @Load 2.16 kg, Temperature 230 °C

- Flexural Modulus: 0.800 GPa

- Melting Point: 110 - 155 °C

- Vicat Softening Point: 105 °C

$ 1680/MT

- Density: 0.951 g/cc

- Melt Flow: 0.30 g/10 min @Load 5.00 kg, Temperature 190 °C

$ 2335/MT

- Density: 1.17 g/cc

- Water Absorption: 0.15 %

- Tensile Strength at Break: 15.0 MPa

- Elongation at Break: 300 %

- Volume Resistivity: 100 ohm-cm @Temperature 23.0 °C

$ 1591/MT

- Density: 1.06 g/cc

- Linear Mold Shrinkage: 0.0060 cm/cm

- Melt Flow: 7.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 30 g/10 min @Load 5.00 kg, Temperature 230 °C

- Hardness, Shore D: 50

$ 1471/MT

- Density: 1.04 g/cc

- Linear Mold Shrinkage: 0.0065 cm/cm

- Melt Flow: 22 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 17.0 MPa

- Elongation at Break: 300 %

$ 1458/MT

- Density: 0.923 g/cc

- Water Absorption: 0.020 %

- Melt Flow: 0.80 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength at Break: <= 3.40 MPa

- Tensile Strength at Break: >= 17.0 MPa

$ 2052/MT

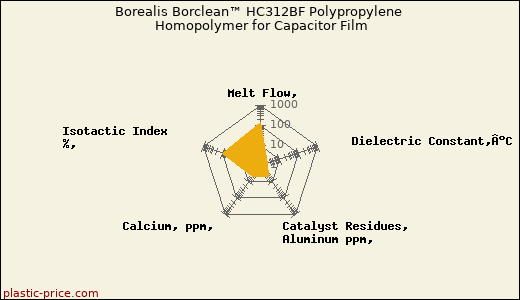

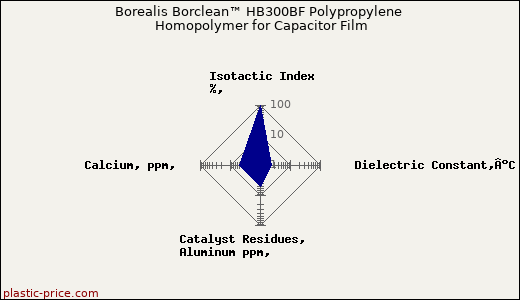

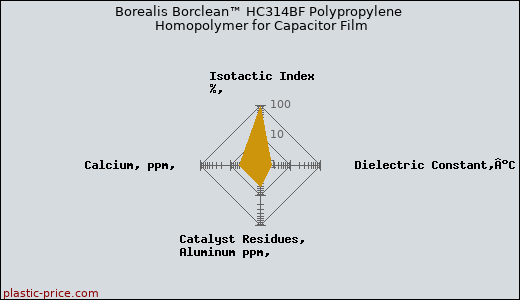

- Melt Flow: 3.7 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ash: 0.0010 - 0.0020 %

- Melting Point: 161 - 165 °C

- Dielectric Constant: 2.25

- Calcium, ppm: 2 max

$ 1589/MT

- Density: 0.964 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 63

- Tensile Strength, Yield: 27.0 MPa

$ 1993/MT

- Density: 0.700 g/cc

- Melt Flow: 1.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 11.0 MPa

- Elongation at Break: >= 50 %

- Tensile Modulus: 2.00 GPa

$ 2193/MT

- Density: 0.900 g/cc

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Shore D: 60

- Tensile Strength, Yield: 28.0 MPa

- Elongation at Yield: 6.0 %

$ 1666/MT

- Density: 0.905 g/cc

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 25.0 MPa

- Elongation at Yield: 13.5 %

- Tensile Modulus: 0.900 GPa

$ 2286/MT

- Density: 1.14 g/cc

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 25 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 132 MPa

- Tensile Strength, Yield: 103 MPa

Borealis BorPEX™ HE2591 High Density Polyethylene Powder for Crosslinked Pipes (Pex-C (Irradiation))

$ 1989/MT

- Density: 0.944 g/cc

- High Load Melt Index: 10 g/10 min @Load 21.6 kg, Temperature 190 °C

- Elongation at Break: >= 600 %

$ 1681/MT

- Density: 0.925 g/cc

- Linear Mold Shrinkage: 0.0015 cm/cm

- Linear Mold Shrinkage: 0.0080 cm/cm

- Melt Flow: 12 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 36.0 MPa

$ 1828/MT

- Density: 0.908 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 12 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 100

- Tensile Strength, Yield: 34.5 MPa

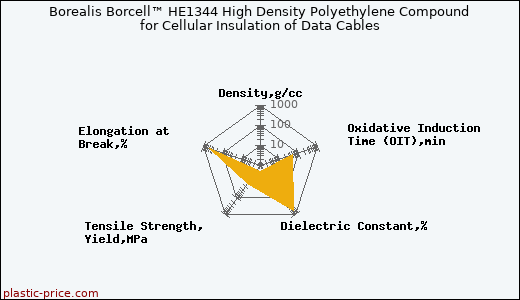

$ 2222/MT

- Density: 0.947 g/cc

- Oxidative Induction Time (OIT): 30 min

- Melt Index of Compound: 3.3 g/10 min

- Dielectric Constant: 2.05 @Frequency 1.80e+10 Hz

- Dielectric Constant: 2.24 @Frequency 3.00e+9 Hz

$ 1498/MT

- Density: 0.900 g/cc

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Shore D: 58

- Tensile Strength, Yield: 22.0 MPa

- Elongation at Yield: 6.0 %

$ 2256/MT

- Density: 0.948 g/cc

- ESCR 10% Igepal®: >= 2000 hour

- Melt Flow: 0.70 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 55

- Tensile Strength, Yield: >= 24.8 MPa

$ 1846/MT

- Density: 0.942 g/cc

- Melt Flow: 1.0 g/10 min @Load 5.00 kg, Temperature 190 °C

- Tensile Strength at Break: 18.0 MPa

- Tensile Strength, Yield: 27.00 MPa

- Elongation at Break: 195 %

$ 1500/MT

- Density: 0.942 g/cc

- Density: 0.952 g/cc

- ESCR 10% Igepal®: >= 5000 hour

- Carbon Black Loading: >= 2.0 %

- Melt Flow: 0.50 g/10 min @Load 2.16 kg, Temperature 190 °C

$ 1886/MT

- Density: 1.12 g/cc

- Linear Mold Shrinkage: 0.0050 cm/cm

- Melt Flow: 2.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Elongation at Break: 2.1 %

- Tensile Modulus: 7.40 GPa

$ 1641/MT

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Flexural Modulus: 0.750 GPa

- Heat Seal Strength Initiation Temperature: 108 °C

- Melting Point: 130 - 134 °C

- Vicat Softening Point: 117 °C

- Haze: 1.0 %

$ 2254/MT

- Density: 1.17 g/cc

- Tensile Strength at Break: 13.0 MPa

- Elongation at Break: >= 75 %

- Elongation at Break: 300 %

- Brittleness Temperature: <= -35.0 °C

$ 2032/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.016 cm/cm

- Melt Flow: 7.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 20.0 MPa

- Tensile Modulus: 0.940 GPa

$ 1526/MT

- Density: 0.940 g/cc

- Linear Mold Shrinkage: 0.0080 cm/cm

- Melt Flow: 17 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 16.0 MPa

- Elongation at Break: 400 %

$ 1752/MT

- Density: 1.04 g/cc

- Linear Mold Shrinkage: 0.0065 cm/cm

- Melt Flow: 22 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 17.0 MPa

- Elongation at Break: 300 %

$ 1537/MT

- Density: 0.923 g/cc

- Environmental Stress Crack Resistance: >= 96 hour @Temperature 50.0 °C

- Melt Flow: 1.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 52

- Tensile Strength at Break: <= 11.25 MPa

$ 1984/MT

- Melt Flow: 2.1 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 40.00 MPa

- Elongation at Yield: 6.0 %

- Tensile Modulus: 2.00 GPa

- Flexural Modulus: 1.90 GPa

$ 1486/MT

- Density: 0.900 - 0.910 g/cc

- Thickness: 50.0 microns

- Melt Flow: 10 g/10 min @Load 2.16 kg, Temperature 230 °C

- Film Elongation at Break, MD: 650 %

- Film Elongation at Break, TD: 850 %

$ 1572/MT

- Density: 0.923 g/cc

- Elongation at Break: >= 300 %

- Elongation at Break: >= 360 %

- Elongation at Break: 400 %

- Melting Point: 135 °C

$ 2367/MT

- Melt Flow: 1.9 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 2.5 g/10 min @Load 5.00 kg, Temperature 190 °C

- Melt Flow: 8.1 g/10 min @Load 5.00 kg, Temperature 230 °C

- Film Elongation at Break, MD: 80 - 100 %

- Tensile Modulus: 1.10 - 1.30 GPa

$ 2408/MT

- Density: 0.900 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 25 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Shore D: 62

- Tensile Strength, Yield: 20.0 MPa

$ 1483/MT

- Density: 0.922 g/cc

- Melt Flow: 2.1 g/10 min @Load 2.16 kg, Temperature 190 °C

- Film Elongation at Break, MD: 350 %

- Film Elongation at Break, TD: 600 %

- Tensile Modulus: 0.200 GPa

$ 1663/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 91

- Tensile Strength, Yield: 28.0 MPa

$ 1797/MT

- Density: 1.05 g/cc

- Linear Mold Shrinkage: 0.0050 cm/cm

- Melt Flow: 13 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 17.00 MPa

- Elongation at Break: 70 %

$ 2565/MT

- Density: 0.936 g/cc

- ESCR 10% Igepal®: >= 2000 hour

- Melt Flow: 0.70 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 54

- Tensile Strength, Yield: >= 24.8 MPa

$ 1774/MT

- Density: 0.900 - 0.910 g/cc

- Thickness: 50.0 microns

- Melt Flow: 0.80 g/10 min @Load 2.16 kg, Temperature 230 °C

- Film Elongation at Break, MD: 600 %

- Film Elongation at Break, TD: 900 %

$ 1887/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Film Elongation at Break, MD: 550 - 750 %

- Film Elongation at Break, TD: 550 - 750 %

- Tensile Modulus: 0.500 - 0.600 GPa

$ 1462/MT

- Density: 1.10 g/cc

- ESCR 10% Igepal®: >= 2000 hour

- Melt Flow: 0.40 g/10 min @Load 2.16 kg

- Melt Flow: 2.0 g/10 min @Load 5.00 kg

- Hardness, Shore D: 59

$ 1490/MT

- Density: 0.935 g/cc

- Melt Flow: 0.70 g/10 min @Load 5.00 kg, Temperature 190 °C

- Melt Flow: 15 g/10 min @Load 21.6 kg, Temperature 190 °C

- Film Elongation at Break, MD: 400 %

- Film Elongation at Break, TD: 650 %

$ 1805/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 110 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 30.0 MPa

- Elongation at Yield: 12 %

$ 1499/MT

- Density: 1.16 g/cc

- Tensile Strength at Break: >= 11.1 MPa

- Tensile Strength at Break: 13.1 MPa

- Elongation at Break: 400 %

- Oxygen Index: 23 %

$ 1465/MT

- Density: 0.905 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 13 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Rockwell R: 86

- Tensile Strength, Yield: 26.0 MPa

$ 1935/MT

- Density: 0.960 g/cc

- Melt Flow: 9.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Coating Weight: 6.00 g/m²

- Melting Point: >= 130 °C

- Vicat Softening Point: 124 °C

- Maximum Coating Weight m/min: 450 min

$ 1531/MT

- Density: 0.946 g/cc

- Melt Flow: 0.20 g/10 min @Load 5.00 kg, Temperature 190 °C

- High Load Melt Index: 6.0 g/10 min @Load 21.6 kg, Temperature 190 °C

- Film Elongation at Break, MD: 300 %

- Film Elongation at Break, TD: 450 %

$ 1454/MT

- Density: 0.945 g/cc

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 190 °C

- Melt Flow: 1.2 g/10 min @Load 5.00 kg, Temperature 190 °C

- Melt Flow: 25 g/10 min @Load 21.6 kg, Temperature 190 °C

- Film Elongation at Break, MD: 100 %

$ 1511/MT

- Density: 0.925 g/cc

- Thickness: 70.0 microns

- Melt Flow: 0.40 g/10 min @Load 2.16 kg, Temperature 190 °C

- Melt Flow: 2.0 g/10 min @Load 5.00 kg, Temperature 190 °C

- Film Elongation at Break, MD: 650 %

$ 1512/MT

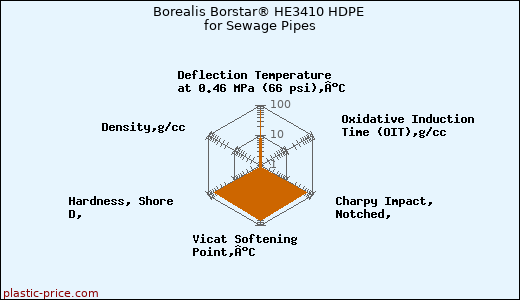

- Density: 0.956 g/cc

- Oxidative Induction Time (OIT): >= 15 min @Temperature 210 °C

- Melt Flow: 0.30 g/10 min @Load 5.00 kg, Temperature 190 °C

- Hardness, Shore D: 60

- Charpy Impact, Notched: 1.40 J/cm² @Temperature 0.000 °C

$ 2037/MT

- Density: 0.956 g/cc

- Environmental Stress Crack Resistance: >= 2000 hour @Temperature 80.0 °C

- Carbon Black Loading: >= 2.0 %

- Melt Flow: 0.30 g/10 min @Load 5.00 kg, Temperature 190 °C

- Tensile Strength, Yield: 22.0 MPa

$ 1468/MT

- Density: 0.948 g/cc

- Melt Flow: 0.30 g/10 min @Load 5.00 kg, Temperature 190 °C

$ 1900/MT

- Density: 0.950 g/cc

- Melt Flow: 0.30 g/10 min @Load 5.00 kg, Temperature 190 °C

$ 1721/MT

- Density: 0.953 g/cc

- Melt Flow: 0.30 g/10 min @Load 5.00 kg, Temperature 190 °C

$ 1732/MT

- Density: 0.953 g/cc

- Melt Flow: 0.30 g/10 min @Load 5.00 kg, Temperature 190 °C

$ 1743/MT

- Density: 0.920 g/cc

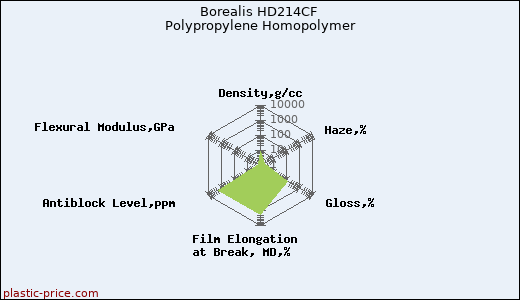

- Environmental Stress Crack Resistance: >= 5.0 hour @Temperature 50.0 °C

- Melt Flow: 0.70 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 50

- Hardness, Shore D: 52

$ 1624/MT

- Density: 0.954 g/cc

- ESCR 10% Igepal®: >= 40 hour

- Melt Flow: 4.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 61

- Tensile Strength, Yield: 22.0 MPa

$ 1483/MT

- Density: 0.940 g/cc

- Density: 0.951 g/cc

- ESCR 10% Igepal®: >= 5000 hour

- Carbon Black Loading: >= 2.0 %

- Melt Flow: 0.20 g/10 min @Load 2.16 kg, Temperature 190 °C

$ 1612/MT

- Density: 0.944 g/cc

- Environmental Stress Crack Resistance: >= 2000 hour @Temperature 80.0 °C

- Melt Flow: 0.80 g/10 min @Load 5.00 kg, Temperature 190 °C

- Tensile Strength, Yield: 19.00 MPa

- Elongation at Break: >= 600 %

$ 1538/MT

- Density: 0.949 g/cc

- Melt Flow: 0.80 g/10 min @Load 5.00 kg, Temperature 190 °C

$ 1697/MT

- Density: 0.958 g/cc

- ESCR 10% Igepal®: >= 100 hour

- Melt Flow: 0.40 g/10 min @Load 2.16 kg, Temperature 190 °C

- Melt Flow: 1.8 g/10 min @Load 5.00 kg, Temperature 190 °C

- High Load Melt Index: 28 g/10 min @Load 21.6 kg, Temperature 190 °C

$ 1989/MT

- Density: 0.951 g/cc

- Environmental Stress Crack Resistance: >= 1000 hour @Temperature 80.0 °C

- Melt Flow: 0.30 g/10 min @Load 5.00 kg, Temperature 190 °C

- Tensile Strength, Yield: 24.99 MPa

- Elongation at Break: >= 600 %

$ 1551/MT

- Density: 0.954 g/cc

- ESCR 10% Igepal®: >= 40 hour

- Melt Flow: 4.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 61

- Tensile Strength, Yield: 22.0 MPa

$ 1960/MT

- Density: 0.937 g/cc

- Melt Flow: 0.40 g/10 min @Load 2.16 kg, Temperature 190 °C

- Melt Flow: 2.1 g/10 min @Load 5.00 kg, Temperature 190 °C

- Film Elongation at Break, MD: 530 %

- Film Elongation at Break, TD: 830 %

$ 1479/MT

- Density: 0.946 g/cc

- Density: 0.958 g/cc

- ESCR 10% Igepal®: >= 2000 hour @Temperature 50.0 °C

- Absorption Coefficient: >= 400

- Carbon Black Loading: 2.5 %

$ 1558/MT

- Density: 0.942 g/cc

- Melt Flow: 0.50 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 61

- Tensile Strength, Yield: 13.8 MPa

- Elongation at Break: 700 %

$ 1873/MT

- Density: 0.934 g/cc

- ESCR 10% Igepal®: >= 300 hour

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength, Yield: 17.9 MPa

- Flexural Modulus: 0.490 GPa

$ 1758/MT

- Density: 0.934 g/cc

- ESCR 10% Igepal®: >= 200 hour

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength, Yield: 19.3 MPa

- Flexural Modulus: 0.558 GPa

$ 1613/MT

- Density: 1.15 g/cc

- Melt Flow: 0.80 g/10 min @Load 2.16 kg, Temperature 190 °C

- Hardness, Shore D: 40

- Tensile Strength, Yield: >= 10.5 MPa

- Tensile Strength, Yield: 13.1 MPa

$ 1516/MT

- Density: 0.923 g/cc

- Density: 0.941 g/cc

- Density: 2.00 g/cc

- Melt Flow: 0.90 g/10 min

- Tensile Strength, Yield: >= 14.58 MPa

$ 1692/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 8.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Slip Level: 1800 ppm

- Film Elongation at Break, MD: 550 - 750 %

- Tensile Modulus: 0.400 - 0.500 GPa

$ 1523/MT

- Density: 1.40 g/cc

- Hardness, Shore D: 50

- Tensile Strength at Break: 12.8 MPa

- Tensile Strength at Break: 16.0 MPa

- Elongation at Break: 220 %

$ 1476/MT

- Density: 0.999 g/cc

- Linear Mold Shrinkage: 0.0095 cm/cm

- Melt Flow: 26 g/10 min @Load 2.16 kg, Temperature 230 °C

- Ball Indentation Hardness: 40.0 MPa

- Tensile Strength, Yield: 20.0 MPa

$ 1580/MT

- Density: 0.950 g/cc

- Linear Mold Shrinkage: 0.011 cm/cm

- Melt Flow: 6.0 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melt Flow: 30 g/10 min @Load 5.00 kg, Temperature 230 °C

- Ball Indentation Hardness: 33.0 MPa

$ 1592/MT

- Density: 0.900 g/cc

- Melt Flow: 1.6 g/10 min @Load 2.16 kg, Temperature 230 °C

- Hardness, Shore D: 63

- Tensile Strength, Yield: 25.0 MPa

- Elongation at Break: <= 200 %

$ 1492/MT

- Density: 0.940 g/cc

- ESCR 10% Igepal®: >= 250 hour

- Melt Flow: 4.0 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength, Yield: 22.1 MPa

- Flexural Modulus: 0.641 GPa

$ 1525/MT

- Density: 0.910 g/cc

- Melt Flow: 18 g/10 min @Load 2.16 kg, Temperature 230 °C

- Neck In: 8.00 cm

- Coating Weight: >= 12.0 g/m²

- Vicat Softening Point: 147 °C @Load 1.02 kg

$ 1520/MT

- Tensile Strength at Break: 11.0 MPa

- Elongation at Break: <= 75 %

- Elongation at Break: 250 %

- Volume Resistivity: 100 ohm-cm @Temperature 23.0 °C

- Volume Resistivity: 100 ohm-cm @Temperature 90.0 °C

- Shelf Life: 12.0 Month

$ 2019/MT

- Density: 0.905 g/cc

- Melt Flow: 2.8 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Modulus: 1.70 GPa

- Flexural Modulus: 1.65 GPa

- Charpy Impact, Notched: 0.500 J/cm² @Temperature 23.0 °C

$ 2132/MT

- Density: 0.923 g/cc

- Density: 1.05 g/cc

- Density: 2.00 g/cc

- Melt Flow: 0.90 g/10 min

- Tensile Strength, Yield: >= 14.58 MPa

$ 1596/MT

- Density: 0.480 g/cc

- Density: 0.945 g/cc

- Oxidative Induction Time (OIT): 50 min

- Tensile Strength, Yield: 13.1 MPa

- Tensile Strength, Yield: 22.8 MPa

$ 2223/MT

- Density: 0.945 g/cc

- Oxidative Induction Time (OIT): >= 200 min

- Tensile Strength, Yield: 13.1 MPa

- Tensile Strength, Yield: 20.0 MPa

- Elongation at Break: 500 %

$ 1506/MT

- Density: 0.934 g/cc

- Density: 0.937 g/cc

- Thermal Stress Crack Resistance: 1.50 hour @Temperature 105 °C

- Oxidative Induction Time (OIT): 50 min @Temperature 200 °C

- Tensile Strength at Break: 11.0 MPa

$ 1937/MT

- Melt Flow: 27 g/10 min @Load 2.16 kg, Temperature 230 °C

- Melting Point: 161 - 165 °C

- Molecular Weight: narrow distribution

$ 2358/MT

- Density: 0.905 g/cc

- Melt Flow: 0.30 g/10 min @Load 2.16 kg, Temperature 230 °C

- Tensile Strength, Yield: 25.0 MPa

- Elongation at Yield: 13.5 %

- Tensile Modulus: 0.900 GPa

$ 1731/MT

- Density: 0.955 g/cc

- Environmental Stress Crack Resistance: 180 hour

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 1.5 g/10 min @Load 2.16 kg, Temperature 190 °C

- Tensile Strength, Yield: 23.0 MPa

$ 1813/MT

- Density: 0.900 - 0.910 g/cc

- Melt Flow: 0.85 g/10 min @Load 2.16 kg, Temperature 230 °C

- Film Elongation at Break, MD: 550 - 750 %

- Film Elongation at Break, TD: 550 - 750 %

- Tensile Modulus: 0.500 - 0.600 GPa

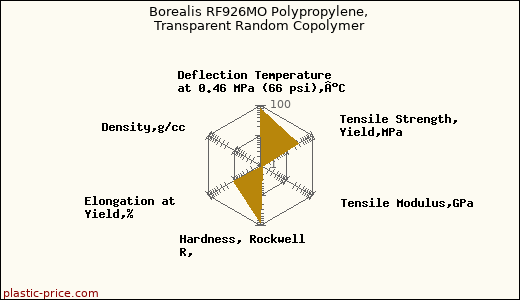

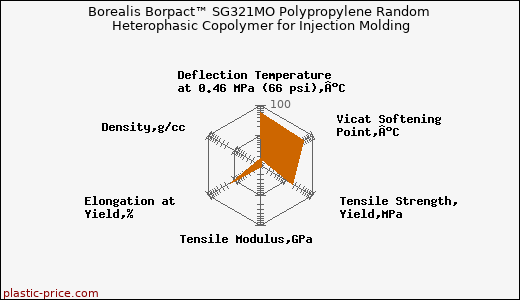

$ 2262/MT

- Density: 0.904 g/cc

- Linear Mold Shrinkage: 0.010 - 0.020 cm/cm

- Melt Flow: 4.0 g/10 min @Load 2.16 kg, Temperature 230 °C

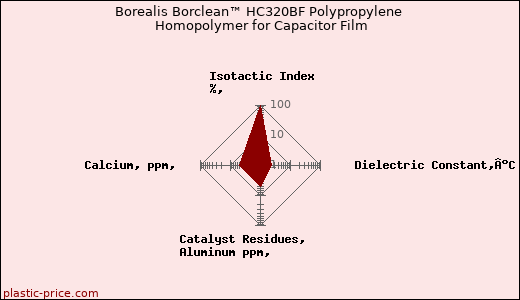

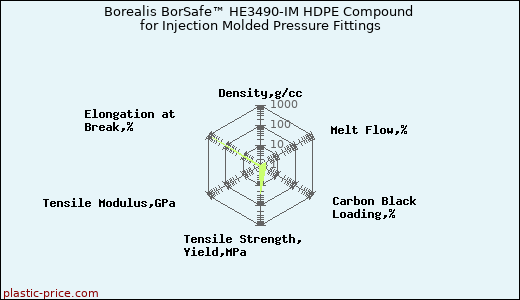

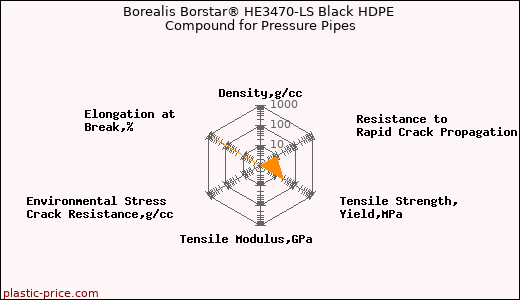

- Hardness, Rockwell R: 80